Contamination is the Culprit

Contamination is one of the quickest ways to spoil a great beer. Beer generally uses a pure single culture of yeast to help produce a consistent fermentation and flavor profile. However, there are many control points in the brewing process where contamination can occur.

Preventing beer contamination and maintaining brand reputation is critical, and beer testing is key. Building a QA/QC program is crucial to detecting unwanted organisms and identifying control points where contamination may occur, which in turn helps brewers find the right solutions.

Where Do I Start?

Microbiological plating is the next tier for maintaining quality in a QA/QC program. If you’re currently building out a QA/QC program and looking for some simple & easy procedures to start with maintaining quality.

Check out some of the links for some of our guides:

Check out some of the links for some of our guides:

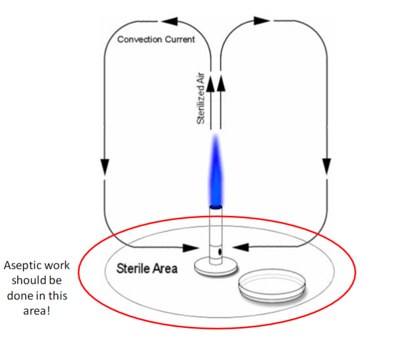

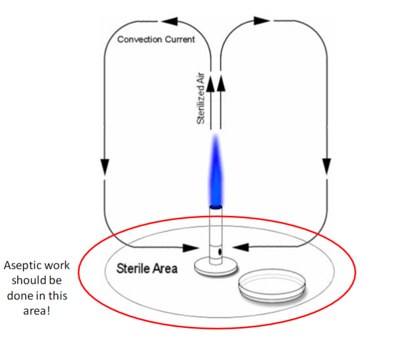

A QA/QC microprogram requires some investment in time and space, such as an aseptic working area, incubator, and experienced microbiology staff. QA/QC labs can be retrofitted into existing spaces fairly easily, as long as the area can be isolated when needed and kept clean. Sometimes, these retrofitted areas are not as efficient, but they can work for your basic QC needs. Construction of a new lab can be more expensive - you will want to plan for utilities, enough power for equipment, gas lines, and other accommodations during buildout.

Aseptic Technique

Procedures that limit the spread of unwanted microorganisms to sterile or pure culture samples by using laminar flow hoods or heated convection currents and sterilized materials are considered “aseptic techniques.”

Find a proper working area with little airflow for Bunsen burners or alcohol lamps to create a sterile environment for sterile samples. Ideally, work is done at benchtop height as that reduces the risk of debris and other organisms closer to the ground.

Once your aseptic space is set up, here are some quick ways to start your microbiological program and a breakdown of common microbiological media that can help identify spoilage organisms.

What Is The Purpose Of Selective Plating?

What Is The Purpose Of Selective Plating?

There are different types of microbiological media for growing and isolating organisms. They usually fall into three different categories.

Nutrient Media

These media contain all the elements that most yeast and bacteria need for growth and are non-selective, so they are used for the general cultivation and maintenance of yeast and bacteria kept in laboratory-culture collections.

Selective Media

Only the growth of certain organisms can be permitted by using a chemical inhibitor such as cycloheximide. Cycloheximide is an antibiotic used to help suppress the growth of most brewing yeast without affecting the growth of common brewery bacteria.

Differential Media

Differential media contain different dyes to distinguish between individual microorganisms. When an acid-producing organism grows on this media, the media changes colors due to the pH change. This can be seen in the picture, with a yellow halo being created around the colony growth.

Differential media contain different dyes to distinguish between individual microorganisms. When an acid-producing organism grows on this media, the media changes colors due to the pH change. This can be seen in the picture, with a yellow halo being created around the colony growth.

Common Brewery Media Explained

.png?width=400&height=271&name=Wallerstein%20Nutrient%20Medium%20(WLN).png)

- Nutrient media allows for the growth and enumeration of many brewery organisms, both yeast and bacteria.

- The medium contains bromocresol green, which acts as a pH indicator, so acid-producing bacteria and yeast will turn the green media yellow.

- Different organisms can also absorb the bromocresol green and appear green in color.

.png?width=400&height=271&name=Yeast%20Extract%2c%20Peptone%2c%20Dextrose%20Medium%20(YPD).png)

- A nutrient media containing yeast extract, peptone, distilled water, and dextrose allows the growth and enumeration of many brewery organisms, both yeast and bacteria.

Good for Bacteria and Wild Yeast Identification

.png?width=400&height=271&name=Wallerstein%20Differential%20Medium%20(WLD).png)

- Cycloheximide is added to Wallerstein Nutrient Medium (WLN) to suppress the growth of Saccharomyces-type yeast.

- The medium contains bromocresol green, which acts as a pH indicator, so acid-producing bacteria and yeast will turn the green media yellow.

- Different organisms can also absorb the bromocresol green and appear green in color.

.png?width=400&height=271&name=Schwarz%20Differential%20AgarLee%E2%80%99s%20Multi-Differential%20Agar%20(SDA.LMDA).png)

- The agar uses cycloheximide to suppress the growth of Saccharomyces-type yeast.

- Calcium Carbonate (CaCO3) aids in the growth and assistance in the identification of acid-producing microorganisms.

- The medium contains bromocresol green, which acts as a pH indicator, so acid-producing bacteria and yeast will turn the green media yellow.

- Different organisms can also absorb the bromocresol green and appear green in color.

Good for Lactobacillus and Pediococcus Identification

.png?width=268&height=400&name=Hsu%E2%80%99s%20Lactobacillus%20%26%20Pediococcus%20Medium%20(HLP).png)

- Selective medium for the detection and enumeration of Lactic Acid Bacteria(LAB).

- Sodium thioglycolate is incorporated into media to maintain a reducing(anaerobic) environment.

- Very user-friendly, autoclaving is not necessary for sterilization in the preparation.

Note: Sometimes wild yeast such as Brettanomyces can grow in this medium

Good for Wild Yeast Identification

.png?width=400&height=271&name=Lin%E2%80%99s%20Wild%20Yeast%20Media%20(LWYM).png)

- This media is designed to encourage the growth of Saccharomyces wild yeast, but some non-Saccharomyces yeast will also grow.

- The growth of most culture Saccharomyces yeast (Beer yeast) is suppressed or reduced by the fuchsin-sulfite and crystal violet in the media.

.png?width=400&height=271&name=Lin%E2%80%99s%20Cupric%20Sulfate%20Media%20(LCSM).png)

- Cupric sulfate in the media suppresses or reduces the growth of most cultured Saccharomyces yeast (beer yeast).

- Wild yeast grows as larger, distinct colonies.

- Although this media is designed to encourage the growth of non-Saccharomyces yeast, a few diastatic/STA1+ Saccharomyces yeast may show some growth.

Let's Start Testing!

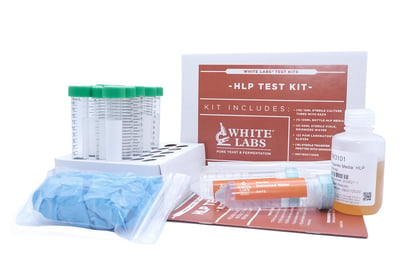

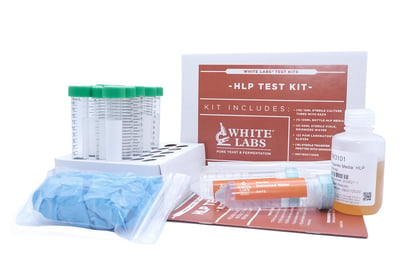

Now that we learned about the common brewery media types, it’s time to start testing! At White Labs, we offer both dry and prepared media as well as an easy start-up test kit to help kick-start your microbiological program!

An all-around kit with SDA, LCSM, and HLP, as well as all the sterile materials needed for plating! Good for testing up to 5-6 samples!!

This is a great starter kit for the detection of Lactobacillus and Pediococcus. It comes with sterile materials and 90mL of HLP for testing up to 5-6 samples!

What Is The Purpose Of Selective Plating?

What Is The Purpose Of Selective Plating? Differential media

Differential media .png?width=400&height=271&name=Wallerstein%20Nutrient%20Medium%20(WLN).png)

.png?width=400&height=271&name=Yeast%20Extract%2c%20Peptone%2c%20Dextrose%20Medium%20(YPD).png)

.png?width=400&height=271&name=Wallerstein%20Differential%20Medium%20(WLD).png)

.png?width=400&height=271&name=Schwarz%20Differential%20AgarLee%E2%80%99s%20Multi-Differential%20Agar%20(SDA.LMDA).png)

.png?width=268&height=400&name=Hsu%E2%80%99s%20Lactobacillus%20%26%20Pediococcus%20Medium%20(HLP).png)

.png?width=400&height=271&name=Lin%E2%80%99s%20Wild%20Yeast%20Media%20(LWYM).png)

.png?width=400&height=271&name=Lin%E2%80%99s%20Cupric%20Sulfate%20Media%20(LCSM).png)