Purpose

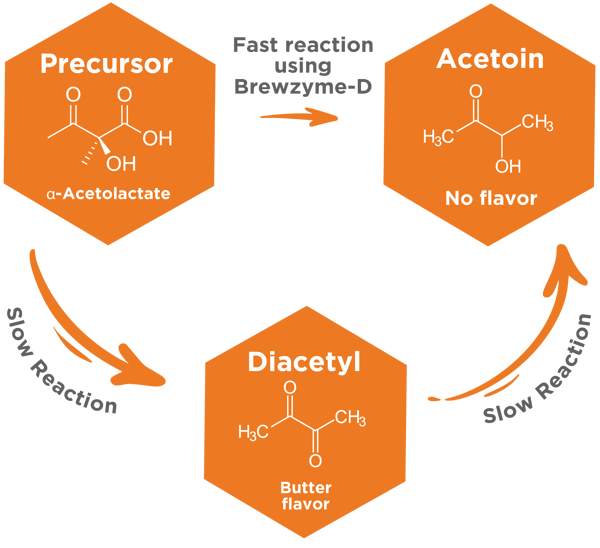

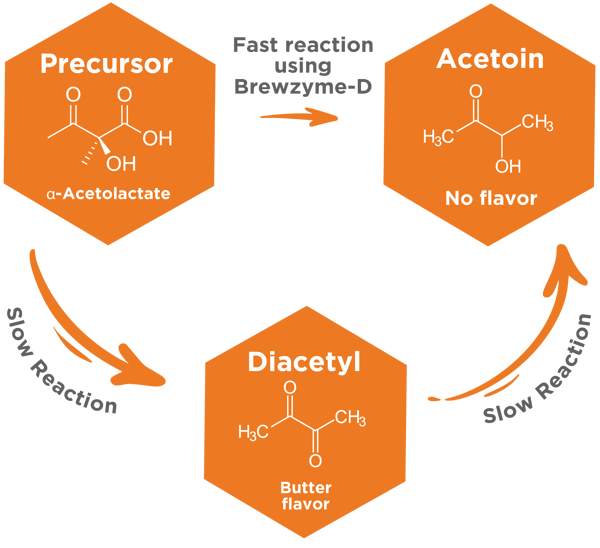

Diacetyl is a common buttery off-flavor that occurs during fermentation. Alpha-acetolactate, the precursor to diacetyl, can also remain in beer after fermentation and is odorless. Once the yeast is removed from beer, this precursor is converted to diacetyl, leaving residual buttery character.

This method is a quick and easy way to ensure diacetyl and its precursor, alpha-acetolactate, have been sufficiently removed from the beer before cold crashing. A beer sample is heated to accelerate the conversion of alpha-acetolactate to diacetyl.

If diacetyl is perceived in the test sample, there is still a significant amount of precursor that needs to be degraded and absorbed by the yeast before cold crashing. We recommend rousing the yeast as well as raising the temperature by 2 to 3 degrees. Packaging beer before validating the absence of alpha-acetolactate can result in conversion to diacetyl and perceivable amounts of buttery off-flavors in the package.

Method

- Heat the water bath to 140-160°F/60-71°C.

- Aseptically collect beer into two 50 mL conical tubes and centrifuge.

- Move beer off sediment into a clean new 50 mL conical tube.

Note: If a centrifuge is not available, cold crash beer sample to get yeast out of solution

- Place one 50 mL tube in the water bath at 140-160°F/60-71°C, while keeping the other at room temperature.

- After 10 to 30 minutes, remove the sample from the water bath and cool to the same temperature as the other sample. An ice water bath or a cold box is effective for cooling.

-

- If you smell the buttery character of diacetyl in either or both samples, let the beer condition longer. Remove cap, smell and taste each sample.

Results

Tips

Tips

- Use a diverse panel of tasters, both trained and untrained, for sensory

- Train your sensory panel, order Diacetyl spikes from Siebel, or use things like yogurt or chardonnay to get accustomed to Diacetyl aromas.

Prevent The Formation of Diacetyl During Fermentation with Brewzyme-D

Brewzyme-D is a new White Labs product that’s designed to be added on the cold side. This ALDC enzyme reduces the flavor of diacetyl and makes more consistent fermentations in shorter times. Made with Alpha Acetolactate Decarboxylase (ALDC).

Dosage:

- Pro (1L, 10L): 15-20mL/hL(0.84 BBL)

- HB (10mL): 10mL/ 20L(5Gal)