Beloved for their clean, crisp, and ultra-drinkable profiles, lagers are the most widely brewed beer in the world. Craft your best lager with these six tips from the pitch!

- Industry Standard is 1.5 - 2 million cells/mL/°Plato

- This refers to the rate of cells needed for repitching after harvesting yeast from a previous beer and is a good rule of thumb.

- Starting Gravity affects pitch rates

- Up to 15°Plato = 1.5 million cells/mL/°Plato

- > 15°Plato = 2 million cells/mL/°Plato

- Temperature of fermentation affects pitch rates

- Pitch at warm temperatures then lower to fermentation temperature after 12 hours = Ale Recommended Pitch Rates (1.0 million cells/mL/°Plato)

- Pitch at cold temperatures = Lager Recommended Pitch Rates (2 million cells/mL/°Plato)

Did You Know: Lab grown yeast like PurePitch® Next Generation is usually pitched at a lower rate due to its glycogen levels, viability, and overall health. You will typically see a range of 7 - 15 million cells/mL with lab grown yeast.

To customize your pitch with PurePitch® Next Generation, visit yeastman.com/calculator!

2. Traditional Method

Lager purists prefer the traditional method of fermentation - knocking out and fermenting at lagering temperatures. Due to the cooler temperatures for the yeast, higher pitch rates are required for successful fermentation. The lower

temperatures result in slower fermentation, with less metabolites (flavor & aroma compounds), creating complexity and a clean, crisp beer!

- Start fermentation between 8-12°C (48-55°F)

- Free rise to 18°C (65°F) at 50-60% attenuation until diacetyl rest is complete (about 2-6 days)

- Once fermentation at or near terminal, cool 2-3°C (4-5°F) per day until hitting lager temperature of 2°C (35°F), collect flocculated yeast

Pro Tip: If you want to adhere to Czech-style tradition, don't exceed fermentation temperatures for diacetyl rest and condition the beer longer at the same temperatures. Ferment cooler and longer when you can for the most delicate flavor profiles.

3. Warm Pitch Method

3. Warm Pitch Method

This method relies on warm yeast pitching temperatures to promote a stronger fermentation and more quickly achieve finished beer. It is a popular method in many craft breweries, allowing for less yeast and shorter fermentation times while still producing great lagers.

- Start fermentation between 15-18°C (60-65°F) and maintain until signs of fermentation are evident, usually within 12 hours (CO2 production or pH decrease)

- After 12 hours of fermentation, slowly lower the temperature to 8-12°C (48-55°F) to limit ester production

- Free rise to 18°C (65°F) at 50-60% attenuation until diacetyl rest is complete (about 2-6 days)

- Cool 2-3°C (4-5°F) per day until hitting lager temperature of 2°C (35°F), collect flocculated yeast

Pro Tip: Pitching warm allows for shorter lag times and an earlier growth phase.

- After 12 hours of fermentation, most ester formation is created within the first 12-72 hours of growth phase and slows when the fermentation temperature is lowered.

- By pitching warm and quickly lowering the temperature, cell growth and maintaining a clean beer profile can be achieved.

4. Fast Lagers

4. Fast Lagers

Modern brewers are finding new ways to produce lagers, including “fast” or “pseudo” lagers, which are untraditional but result in clean, lager-like profiles.

Psuedo Lagers

“Pseudo” lagers fermented with Kveik strains have gained popularity for their ability to ferment fast, at ale temperatures, and for their crisp lager profile. Brewed like an ale, tastes like a lager.

Spund for FUN - High Pressure Lagers

Fermenting under pressure is a way to quicken fermentation timelines by fermenting hotter without the usual risk of “off-flavors”. Pressure reduces yeast growth which reduces metabolite production and inhibits some Acetyl-CoA formation.

Always Check The Viability Before Repitching

- Start fermentation between 18-20°C (65-68°F)

- Set spunding valve to 1 bar (15psi)

- Once terminal gravity is hit cool 2-3°C (4-5°F) per day until hitting lager temperature of 2°C (35°F)

- May allow for a warmer fermentation temperature with reduced metabolite production

- Pressure reduces yeast growth. Less yeast growth can result in lower esters

Pro Tip: Beer under pressure clears slower, so use findings or a more flocculent strain.

Pro Tip: Want to double batch your high pressure lager? Don't set the spund valve until the full batch of wort is added.

5. Identifying Lager vs Ale Strains

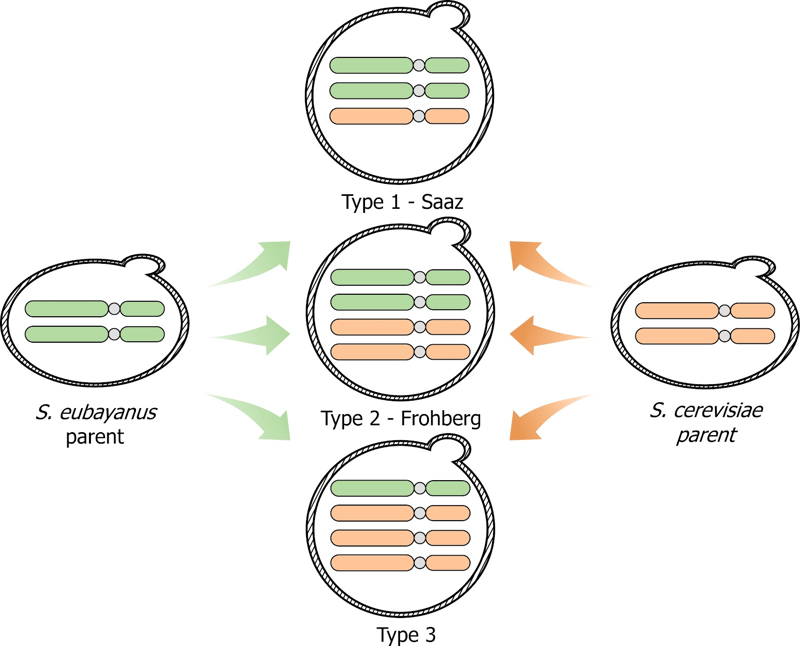

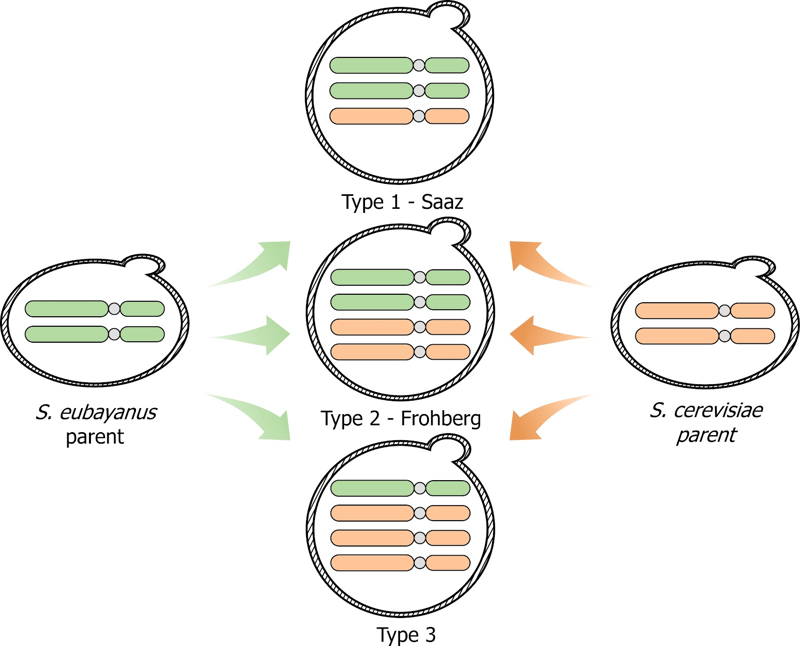

The latest data indicate that two main hybridization events occurred, yielding two larger groups of lager strains (Fig. 1):

- Saaz

- Includes the original strain isolated at Carlsberg. These strains contain more S. eubayanus genome than S. cerevisiae and can ferment cleaner at colder temperatures but does not ferment maltotriose.

- Frohberg

- This includes the strain originally isolated at Heineken, W-34/70, and most of the commercially used strains today. Produces more aroma compounds but also drier beers.

Figure 1. Schematic of lager strains hybridization.

6. Products for Lagers

Lager Yeast Strains

Alternative Yeast Strains

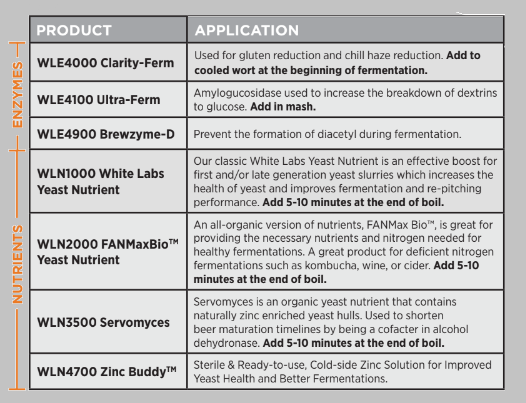

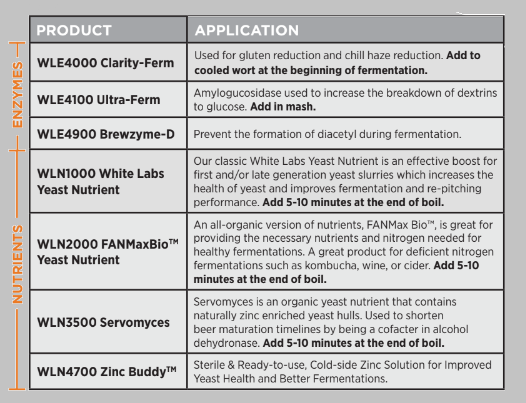

Enzymes & Nutrients

4. Fast Lagers

4. Fast Lagers