In part 2 of this technical series, we will expand on how to communicate the many flavor of fermentation by exploring ways to describe yeast-influenced flavor/aroma compounds & ways we can influence common off-flavors such as acetaldehyde, diacetyl, and sulfur.

Many Flavors of Fermentation Video Playlist

Yeast & Flavor

- Choosing the right yeast strain can be the difference in a huge impact in an overall beer's flavor and aroma

- 59% of beer aroma descriptors are yeast derived from or modified by yeast

- Each Strain differs in the levels of flavor compounds produced

Table 1: Example of a Few Aroma & Flavor Compounds produced by Yeast Fermentation

| Alcohols |

Acids |

Esters |

Others |

| Ethanol |

Acetic |

Ethyl Acetate |

CO2 |

| Propanol |

Caproic |

Isoamyl Acetate |

Acetaldehyde |

| Butanols |

Caprylic |

Isobutyl Acetate |

Diacetyl |

| Amyl Alcohols |

Lactic |

Ethyl Butyrate |

H2S |

| Glycerol |

Pyruvic |

Ethyl Hexanoate |

|

| Phenethyl Alcohol |

Succinic |

Ethyl Octanoate |

|

Esters

- Perceived descriptors: Fruity, floral, banana, apples, perfume, solvent, nail polish remover

- Esters are created by the reaction of an alcohol group with an acid catalyzed by enzymes. Generally fruity or floral these compounds can be prominent in some beer styles and add complexity to beer.

- Esters are very yeast strain and condition specific. Each strain creates unique profile of esters and to some extent can be manipulated by the Brewer to increase or decrease metabolites by changing fermentation temperature, pitch rates or aeration.

Table 2. Comparison between 2 different strains

Phenols

- Perceived descriptors: Clove, black pepper, smoke, herbal

- Strains that produce phenolic compounds must possess specific genes

- Natural mutation in most brewers yeast prevent phenol production

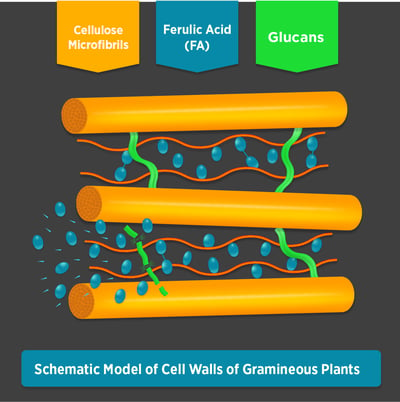

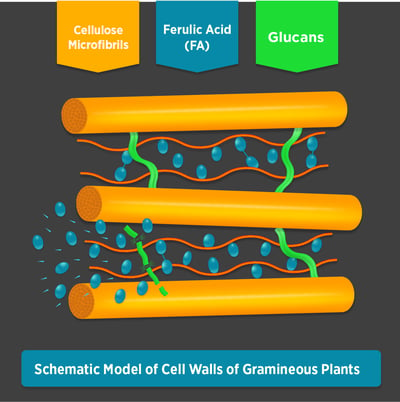

Brewing malted grains, particularly wheat, contain relatively high amounts of ferulic acid, a hydroxycinnamic acid, in the cellulosic structure of the husk

During brewing, ferulic acid is released during the mashing phase. The amount of free ferulic acid in wort increases significantly if a rest is performed at 43C, or if enzymes (namely glucanase) are added to the mash.

The ferulic acid present in wort can be enzymatically or thermally converted to 4-vinyl guaiacol (4-VG), which imparts spicy, pungent, clove-like notes to the beer.

Some moderate levels of 4-VG are formed during boiling, usually below the flavor threshold.

However, the main source of 4-VG is the enzymatic conversion of ferulic acid by the yeast. The conversion is strain-specific, and it only happens when the yeast strain has a functional copy of the gene PAD1, also known as Phenolic Off-flavor (POF+). Strains lacking this gene cannot perform the enzymatic conversion, and are known as POF-.

The levels of the 4-VG present in beer are highly dependent on the yeast strain, the mashing process, and the grist composition.

Fusel Alcohols

- Perceived descriptors: Hot, solventy, paint thinner

- Fusel alcohol formation is greatly related to conditions that promote cell

growth such as temperature, aeration, & nitrogen

- There are approximately 40 fusel alcohols found in beer

- High levels are considered an off-flavor, although higher gravity beers may

contain a background note that can be deemed acceptable

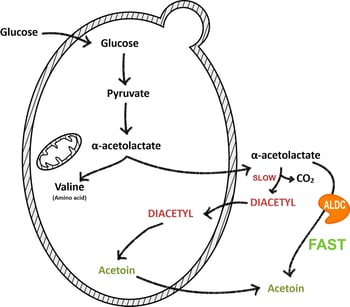

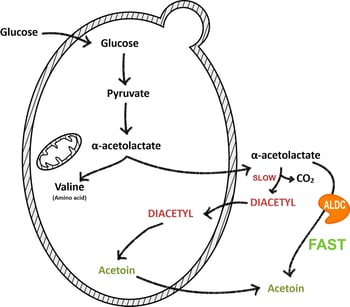

Diacetyl

- Perceived descriptors: Buttery, buttermilk, milky, oily. It can cause a slippery or slick sensation on the palate

- Found in all beer fermentations, ⍺-acetolactate produced by yeast leaks out of the cell and is chemically oxidized into diacetyl

- Yeast will reabsorb diacetyl and reduce it to acetoin, a diacetyl rest can help speed up the process

- Most styles diacetyl is considered an undesirable flavor, but in select styles it can be accepted in small quantities

Acetaldehyde

- Perceived descriptors: Bruised apples, green apples, squash-like, latex

paint

- Found in all beer fermentations, important intermediate step in the production of ethanol

- Generally considered an Off-flavor besides having low amounts in American lager & kellerbier

Acids

- All fermentations produce varying levels of organic acids (usually below

threshold)

- These acids are an integral part of ester formation

- High levels of acids more common in wild/spontaneous due to acetic acid

bacteria, lactic acid bacteria, and some wild yeast

Lactic Acid

- Perceived descriptors: Tart, tangy, sour

- Common in traditional Belgian sour beer and Kettle sours

Acetic Acid

- Perceived descriptors: Vinegar, pungent, sour

- Can come from Acetic Acid Bacteria or Brettanomyces

Sulfur

- Yeast produce large quantities of sulfur compounds during fermentation

- More commonly detected in lager fermentations due to low vigor & high solubility at cold temperatures

Sulfur Dioxide (SO2)

- Perceived descriptors: Burnt matches

Hydrogen Sulfide (H2S)

- Perceived descriptors: Rotten Eggs

Education Is At The Core Of White Labs

Step beyond the basics and dive deep into the science of fermentation in our practical, hands-on 2-day (or 3-day!) Yeast Essentials Workshop, designed for all beverage-makers who are serious about upping their game.

Whether you're refining your yeast harvesting practices or starting a quality control program, this workshop delivers powerful tools and advanced techniques to elevate your fermentation operations!