For decades, brewers have worked around yeast limitations, recycling from cone to cone, managing variability, and adjusting expectations. But yeast is alive, and even small shifts can cause significant differences in fermentation. That's where technology meets tradition. Over our 30 years of business, we have tinkered with the best ways to provide the best yeast possible while making the pitching process easier.

If you are still pitching with traditional methods, you are likely giving up consistency, tank time, and generational reuse without realizing it. This post breaks down what has changed and how brewers are regaining control.

What defines next-generation pitching? Here are five advancements that are driving the shift.

1. Healthier Cells for Fermentation

Traditional

Storing yeast in a plastic container leads to CO2 build-up, which can rapidly deplete yeast viability. From transit to pitching, that CO2 build-up can be toxic to yeast, leaving you with fewer cells available for fermentation. With our FlexCellTM Technology, there is no more exploding or expanded packaging to deal with.

PurePitch® Next Generation

PurePitch® Next Generation Pouches is our cutting-edge, double-patented liquid yeast delivery system in a modular, CO2-releasing film. Our yeast is grown inside our FlexCellTM Technology for maximum yeast health and freshness, then delivered in a concentrated slurry of a whopping 2.15 billion cells/mL for most strains. With over <95% viability and high glycogen reserves, our yeast is ready for that next batch to brew. With higher viability and glycogen reserves means shorter lag times and better fermentation.

The double-layer film is FlexCellTM Technology made to produce the most sturdy package for global shipping. Its high CO2 release rate keeps the yeast at the highest viability possible.

Our liquid yeast has an amazing viability shelf life of 5-7 months from the QC-release date labeled on the package, which is unheard of in liquid yeast production.

What this means for you: Healthier cells to pitch for fermentation means a better fermentation for speed and flavor. Unhealthy cells may cause lag times or unwanted "off-flavors".

2. Stop Guessing Pitch Rates: Build Repeatable Batches on Purpose

Scheduling and planning become easier with a more consistent fermentation timeline. A more consistent fermentation timeline can be accomplished with a consistent pitch rate. Pitching blind or adding yeast quantity variables to each batch of beer can lead to various problems.

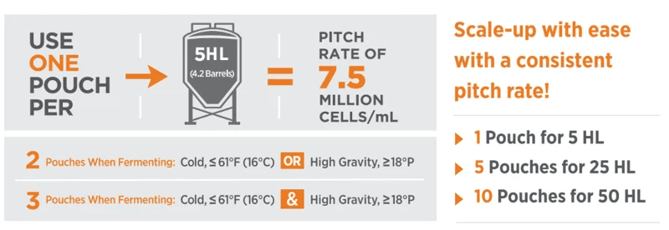

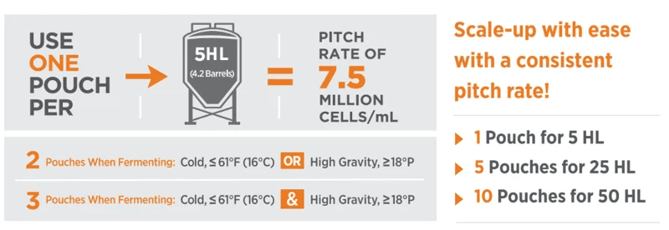

Through best practices from the beer industry, an industry-recommended ale pitch rate of 7.5 million cells/mL leads to consistent fermentation with a fast timeline, while creating flavorful beer. Another benefit of these pitch rates is the adequate growth and budding of cells in each batch of beer, leading to better generational usage.

Traditional

Moving yeast from cone to cone or not monitoring your yeast can lead to pitch rate problems. Over or under-pitching can have many flaws and can affect:

- Variable Flavor Production & Rise of "Off-Flavors"

- Fermentation Speed, such as Slow/Stalled Fermentation

- Flocculation Issues

- Different Harvest Volumes Yields

- Health of Future Generations

PurePitch® Next Generation

Our professional size is 1 Pouch per 5 HL, an industry-recommended ale pitch rate of 7.5 million cells/mL. We also offer a nano size perfect for 1-3 barrels and a homebrew size ideal for 5 gallons, all provided at the recommended ale pitch rate. The modular sizing makes it very convenient to calculate how much to use.

Sizing up, depending on your brewing needs, is also easier than ever. We recommend doubling your pouches when starting your fermentation below 61℉/16℃ or at a higher gravity of 18P or higher.

We recommend tripling your pouches for a robust fermentation if your fermentation has both factors.

What this means for you: No more guessing pitch rates and having variable fermentation performance. An easy scalable size offering an industry recommended pitch rate that is perfect for performance and cell growth for maximum generational reuse.

3. Better Mixing with Pitching with FlexPump

How often have we fumbled over cutting open a yeast packet or exposing the fermenter to outside exposure for too long? Proper mixing can be a key variable in determining whether a fermentation has started. PurePitch® Next Generation Pouches were designed in conjunction with the FlexPump to address these issues.

Traditional

Pitching in during or after a knockout may leave the yeast unhomogenized and stuck at the top of the fermenter. This can lead to slower fermentations as the yeast interaction is inefficient.

PurePitch® Next Generation

The FlexPump is a closed-system pump design that minimizes exposure to contaminants and is pitched in-line for maximum efficiency. Its one-switch operation ensures simplicity, and equipped with a back-flush mechanism, the FlexPump enables maximum yeast efficiency by pitching every last drop.

- Minimize Exposure

- Pitch in Line for Better Homogenization = Faster Fermentations

- Better incorporation of yeast = better transportation of flavors & aromas

- Can be used with our other products like Clarity Ferm, Brewzyme-D, Zinc Buddy, or attached with other products such as fruit purees for a quick attachment & transfer.

What this means for you: Less exposure means less risk of a contamination. With in-line mixing, there is a potential for more yeast interaction for shorter lag times and faster & healthier fermentations.

4. Strain Information Technology At Your Fingertips

It’s key to track every aspect that it put into a beer. From malt, hops, & water certificate of analysis, yeast is no different. Tracking key parameters from the yeast as well as it’s purity can be key for a great tasting beer. All you have to do is scan a QR code.

Traditional

Usually, yeast is provided with a strain name or number and lot number but the more information on your yeast, the better!

PurePitch® Next Generation

Due to our long propagation method of 21 days and 38 quality checkpoints, we believe in building the most robust and healthiest yeast cells. We want to provide transparency with a convenient and ready-to-use QR Code.

A QR code on each package directs you to all the information you need to make the best beer:

- Quality Report - Showcasing Purity, Viability, Lot#

- Strain Info

- Yeast Calculator - For Pitching the Perfect Amount

- Viability Calculator - Help predict shelf-life degradation

White Labs is the industry leader in quality with the same quality and care taken for every culture, including proprietary qPCR methods (developed with Invisible Sentinel) for higher limits of detection. The online pitch rate calculator will recommend the right amount of yeast for a foolproof fermentation or allow you to customize the amount based on your desired pitching rate.

What this means for you: Know about the yeast you're pitching, from how it passed through White Labs QA/QC to estimating it's potential viability. A quick scan reveals all the strain data.

5. With Sustainability In Mind

Brewing science doesn't stop at flavor. Every decision in the brewhouse, from yeast propagation to packaging, leaves an environmental footprint.

Traditional

There can be a lot of waste from brewing from 7 gallons of water used for every 1 gallon of beer. To the use of hard plastics used for yeast packaging. Like you we aim to improve our efficiency to leave a better environmental footprint.

PurePitch® Next Generation

With PurePitch® Next Generation Pouches, we've designed a process that respects both your craft and the planet. Thanks to our optimized FlexCell process, our pouches uses 70% less plastic than before and is 58% less plastic than traditional liquid yeast packaging*. We are committed to the environment and continuously working to reduce our carbon footprint, including even greener packaging.

How to recycle:

Caps can be removed and recycled curbside

Recycle pouch at your local retail store with #4 plastics collection programs

*based on competitors' rigid packaging

What this means for you: We're always looking for the greener option as well, by choosing White Labs from our PurePitch® Next Generation Pouches to the ice packs you receive, we also believe in making the world more sustainable.

Ready To Take The Next Step?

Choose Your Path

▢ Learn how to cell count and reuse yeast — Download the Fermentation Controls: Pitch Rate & Cell Counting Playbook

Start with one batch and benchmark the difference

Tune into our next blog, evolving on how brewers can control pitch rates to affect fermentation performance & flavors and optimize their yeast depending on beer style.