Introduction to Acetaldehyde

Acetaldehyde is a natural byproduct of yeast fermentation and a precursor compound to alcohol. It is an “off-flavor” known to have the aroma and taste of green apple or pumpkin rind. It can be commonly referred to as “green” beer or unfinished beer. Factors influencing the acetaldehyde levels in beer are yeast strain selection, fermentation temperature, and maturation time.

Compound Spotlight: Acetaldehyde

Category: Usually undesirable, Precursor to Ethanol

Aroma: Green apple, pumpkin rind

Threshold (in beer): 5-10ppm depending on the style

What is Acetaldehyde and How is it Formed?

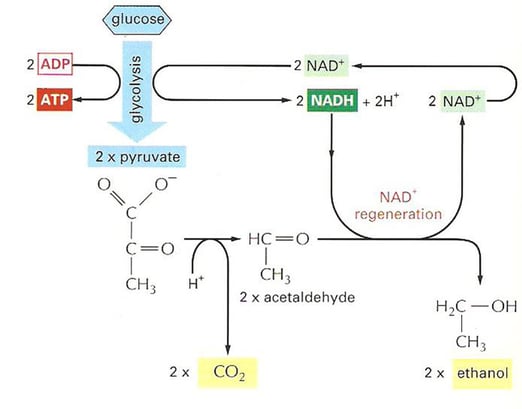

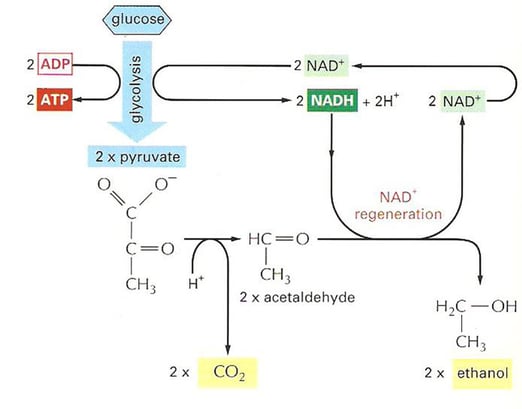

All yeasts form acetaldehyde. As yeast undergoes fermentation, glucose is turned into pyruvate, then acetaldehyde, and finally ethanol. Yeast utilizes this glycolysis metabolic pathway to maintain levels of ATP, adenine triphosphate, the cell's energy currency.

Controlling Acetaldehyde

If acetaldehyde is always present in all yeast metabolisms, how do we control it? High levels of acetaldehyde are usually associated with green or young beer. As you let the beer mature and condition on the yeast, yeast cells will reabsorb the acetaldehyde and convert it to ethanol. Higher fermentation temperatures can speed up fermentation timelines, but they will also cause more compounds to be produced, such as acetaldehyde. Dialing in conditioning time and temperature will help control acetaldehyde formation and clean-up. Healthy and robust yeast can also accelerate and shorten these timelines.

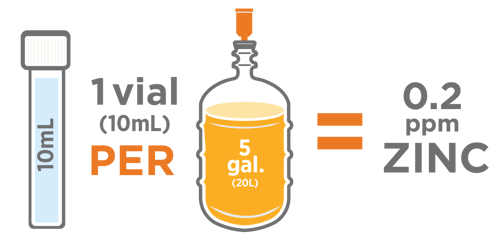

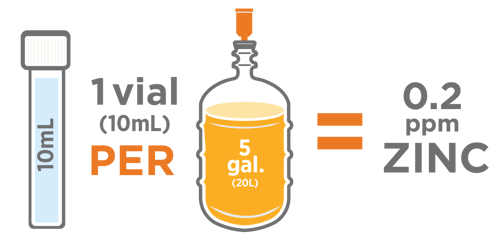

Adequate zinc levels can help build healthy yeast, as it aids in the yeast’s ability for protein synthesis and yeast growth, meaning healthy generations for those that repitch. Zinc is a cofactor in the enzyme alcohol dehydrogenase, helping facilitate and speed up the reaction from acetaldehyde to ethanol. Almost like a daily vitamin, giving yeast and extra charge to complete it’s metabolic functions. Target zinc levels range from 0.15 to 0.5ppm for healthy fermentations.

Adequate zinc levels can help build healthy yeast, as it aids in the yeast’s ability for protein synthesis and yeast growth, meaning healthy generations for those that repitch. Zinc is a cofactor in the enzyme alcohol dehydrogenase, helping facilitate and speed up the reaction from acetaldehyde to ethanol. Almost like a daily vitamin, giving yeast and extra charge to complete it’s metabolic functions. Target zinc levels range from 0.15 to 0.5ppm for healthy fermentations.

Zinc Buddy™ is a sterilized, ready-to-use zinc solution that removes the guesswork of your cold-side zinc additions. Sterilized and acidified to ensure maximum solubility and uptake, Zinc Buddy™ makes your cold-side process easy enough to use on every batch. Just add it while pitching your yeast to ensure proper homogenization.

Other option for Zinc, Servomyces is an organic yeast nutrient that contains naturally zinc-enriched yeast hulls, which can help reach target zinc levels when added to the hot side. We generally recommend 5-10 at end of boil or in the whirlpool for adequate mixing of the nutrient.

Testing

Testing

Through White Labs Analytical Laboratory, we can provide quantitative results to help track acetaldehyde and zinc levels.

Comprehensive Flavor Profile - SIT0031- Panel for monitoring and analyzing common esters and fusel alcohols. Contains acetaldehyde in the panel.

Zinc - SIT9001 - Great for determining zinc levels of wort before fermentation.

Adequate zinc levels can help build healthy yeast, as it aids in the yeast’s ability for protein synthesis and yeast growth, meaning healthy generations for those that repitch. Zinc is a cofactor in the enzyme alcohol dehydrogenase, helping facilitate and speed up the reaction from acetaldehyde to ethanol. Almost like a daily vitamin, giving yeast and extra charge to complete it’s metabolic functions. Target zinc levels range from 0.15 to 0.5ppm for healthy fermentations.

Adequate zinc levels can help build healthy yeast, as it aids in the yeast’s ability for protein synthesis and yeast growth, meaning healthy generations for those that repitch. Zinc is a cofactor in the enzyme alcohol dehydrogenase, helping facilitate and speed up the reaction from acetaldehyde to ethanol. Almost like a daily vitamin, giving yeast and extra charge to complete it’s metabolic functions. Target zinc levels range from 0.15 to 0.5ppm for healthy fermentations.