The Stressful Life of Brewers Yeast

Think back to last summer, that hot day of yard work breaking a sweat and quenching your thirst with that satisfying blond ale. How was that beer created? What ingredients and processes went into crafting its perfect balance and complex flavors?

The yeast used to ferment that beer had undergone a long journey of hundreds (or even thousands of years! It wasn’t easy, but brewers yeast (Saccharomyces cerevisiae) is a hearty organism capable of withstanding strenuous conditions.

Aspirations or Propagation?

Yeast aspires to replicate, consume nutrients and become the dominant culture in the wort to ensure it protects (and consumes) the available nutrient sources. The yeast cells’ goal is to survive and thrive. To do this, it looks to make as much adenosine triphosphate (ATP), an organic compound that drives many functions of the cell, as possible. When yeast respire it makes 36 ATP from each molecule of glucose whereas when yeast are in fermentation it will only make 2 ATP.

Respiration is required for yeast propagation. So what is propagation? Simply put, propagation means growing.

The yeast cells’ goal is to survive and thrive.

When oxygen is present, yeast will replicate and take in nutrients such as carbohydrates, amino acids, minerals, and vitamins (except oxygen, most are provided by barley). Essentially, to increase biomass and the number of yeast cells, yeast needs a constant supply of oxygen in order to stay aerobic, produce ATP, and replicate. But in beer, it's more akin to running a marathon, where yeast must persevere against unideal conditions such as anaerobic environments, alcohol levels, low pH, and high IBU levels.

Brewers, Stressing Yeast Out Since 7,000BCE

In beer, besides producing alcohol, yeast contributes more than 500 flavor and aroma compounds, ultimately leading to the subtleties and complexity of alcoholic beverages. It is the brewer’s art to formulate recipes, and strain selection is crucial. Strains have different levels of attenuation, various flavors, and aroma production that can determine the myriad beer styles.

Yeast contribute more than 500 flavor and aroma compounds

Bakers and brewers both have a special relationship with making it part of two of the world's most popular foods!

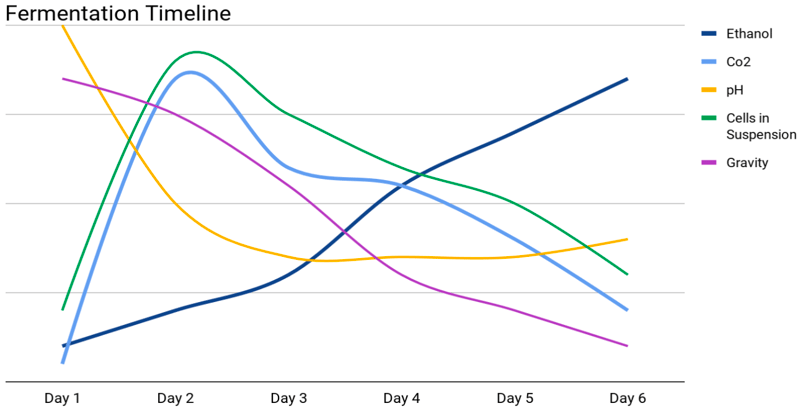

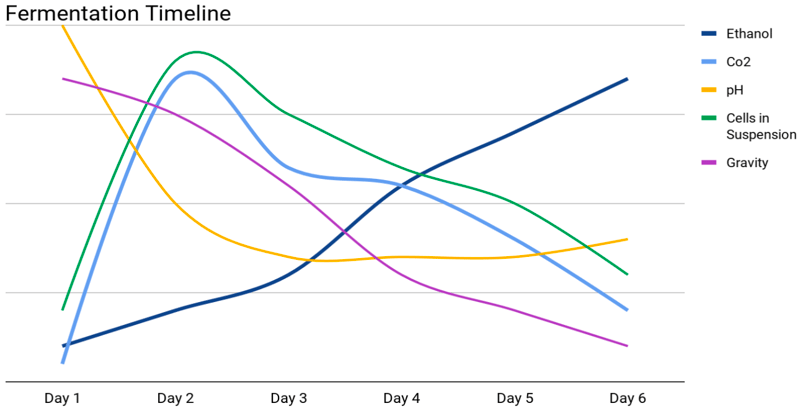

Figure 1. Visual Timeline of A Beer Fermentation

What's happening in the fermentor?

- Early fermentation (Lag Phase) - Yeast uses all the dissolved oxygen; there is no/little detectable uptake in glucose

- 8-16 hours - First sign of active fermentation

- 24 hours (Exponential Phase) - budding yeast cells observed, the temperature, if uncontrolled rises due to heat generated by the fermentation

- 24-48 hours (Stationary Phase) - the rate of yeast growth and carbohydrate assimilation reaches a maximum

- Post 48 hours (Death Phase) - The pH falls to a minimum of 3.8 - 4.4 before rising slightly towards the end of fermentation

Generation 1 and Beyond

Generation 1 sounds more like a ship from Star Trek than it does part of a life cycle of a yeast culture. Fortunately for us (the brewers and consumers), we’ve been able to manipulate the environments where yeast is used to create flavorful and consistent beers, wines, spirits, and more multiple times from the same seed culture.

Once a culture has undergone fermentation it can often be reused, being mindful there are parameters you should follow when reusing yeast. This gives brewers the ability to create a lineage of culture and ferment multiple batches from the same lab-grown pitch of yeast.

When a culture is used to exhaustion it will begin to show large populations of dead yeast and performing less than adequate performance. At that point, it’s best to start the process over again.

So the next beer you enjoy, spend a minute thinking about the yeast responsible for making the beverage you’re enjoying!