Yeast health is critically important for building a successful brewing operation. It not only supports consistent, high-quality beer production, but also drives financial performance through shorter tank residency times, fewer off-target batches, and increased generational re-pitching of yeast cultures.

We will explore what yeast health actually means, how to monitor it, and the key fermentation controls that can improve performance. When brewers dial in these variables, they can accelerate fermentation timelines, improve flavor and aroma quality, and extend the generational lifespan of their yeast.

Viability

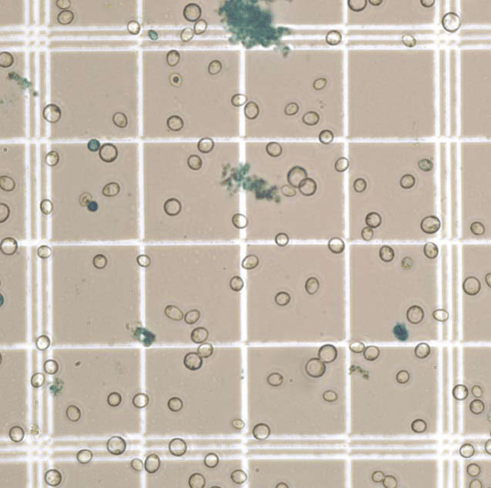

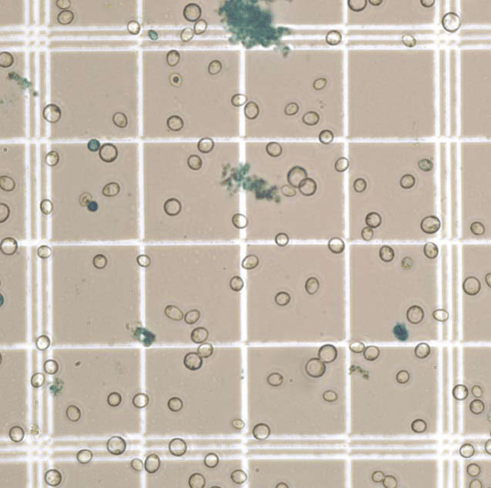

Viability measures the percentage of living yeast cells within a culture, defined as a cell's ability to exhibit life functions. For example, a culture with 90% viability means 90 out of every 100 yeast cells observed are alive. This is determined by a cell's ability to expel a stain which can be seen in the image below. Clear cells are considered alive and those with stain remaining within the cell membrane are dead.

How to Measure:

- Viability Staining

- Cellometer analysis

Need Supplies?

Discover White Labs Lab Supplies for all materials required to perform viability & cell count testing. Download our step-by-step guide for cell counting below!

Vitality

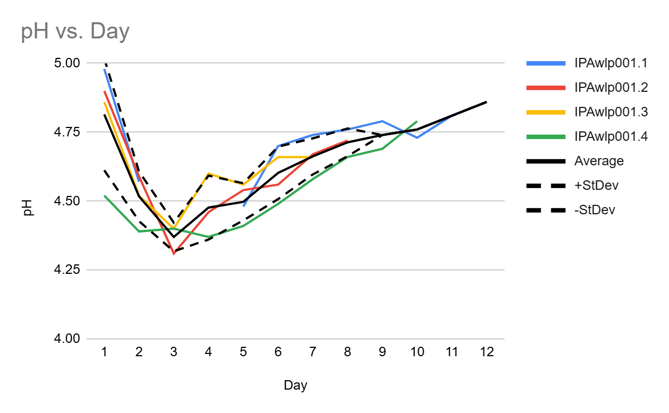

Vitality represents the metabolic fitness of a yeast cell, defined by its potential to endure stress and still perform a quality fermentation. The simplest way to ensure you are using a culture with good vitality is by tracking the attenuation and pH. If attenuation is dropping slowly, leading to an extended fermentation timeline, or the pH does not show a steep drop in the first 48-72 hours, it may signal the culture isn't appropriately enduring the stress of the fermentation. This can occur despite good viability numbers because a cell can be both living and experiencing poor fitness.

Measuring Can be Difficult:

- Not Standardized

- Can use Lugol's iodine to look at glycogen degradation

- Observing attenuation and pH data of fermentation is most practical

Yeast Nutrition

The following are consumable nutrients for a yeast cell that support metabolism through the fermentation process. It is important to consider that a deficiency or excess of each may lead to poor performance or shorter generational use of the culture.

Carbohydrates (sugars)

The sugars supplied from barley malt provide the energy source for yeast cells. Typically, barley provides a healthy array of sugar molecules for brewer's yeast, with maltose being the most prominent. Consider carbohydrates affect on yeast health if:

- Brewing high-gravity wort as it often allow less growth because sterol reserves are strained. Suggested to increase pitch rate.

- "Catabolite repression" - Using a large dose of a simple sugar source pre- or early fermentation can cause the yeast to metabolize these sugar types first, essentially becoming lazy and leaving more complex sugars behind. This can lead to under-attenuation or reduced vitality.

Free Amino Nitrogen (FAN)

Free Amino Nitrogen (FAN) provides yeast a nitrogen source for amino acids. These are the building blocks of proteins that are used in every function of the cell; supporting proper cell growth, metabolism, and flavor production.

Fortunately, all-malt wort is usually sufficient in FAN for a healthy fermentation. You will want to measure FAN levels and dose accordingly if you're producing a low-gravity wort, high-adjunct wort, or beyond beer beverage (seltzer, mead, cider, etc.).

Insufficient levels may cause undesirable flavors or aromas (fusel alcohols), under-pitching affects from poor cell growth, or weaken cell vitality resulting in less generational re-pitching.

Check out our WLN2000 FANMax Bio Yeast Nutrient providing an all-organic nitrogen source for any and all fermentations lacking adequate FAN levels!

Minerals

Minerals support healthy fermentations by supporting key functional pathways within the yeast cell. For example, zinc is a specific cofactor for alcohol dehydrogenase, an enzyme responsible for converting acetaldehyde to ethanol. Magnesium is a cofactor in many of the metabolic steps prior to this final conversion. Calcium functions in key yeast flocculation pathways helping healthy cells drop out of solution and into your harvested slurry.

Similar to FAN, wort typically provides adequate levels of these essential minerals with one exception, zinc. This can be detrimental for yeast health because zinc is critical in many cellular functions. Low levels have been shown to affect cell budding and the yeast cell cycle, membrane integrity, protein synthesis, and/or enzymatic activity among many other functions.

Zinc deficiency is common because it binds to trub on the hot-side of the brewing process and does not make it into the fermenter at sufficient levels. This can cause a wide disruption in overall cell health. It is key to ensure each fermentation is hitting the target ppm levels for zinc.

Target range: 0.15 - 0.5ppm (Optimal typically around 0.275ppm)

Be sure to check out our sterile, ready-to-use cold-side zinc solution,

WLN4700 Zinc Buddy!

Health in The Growth Phase

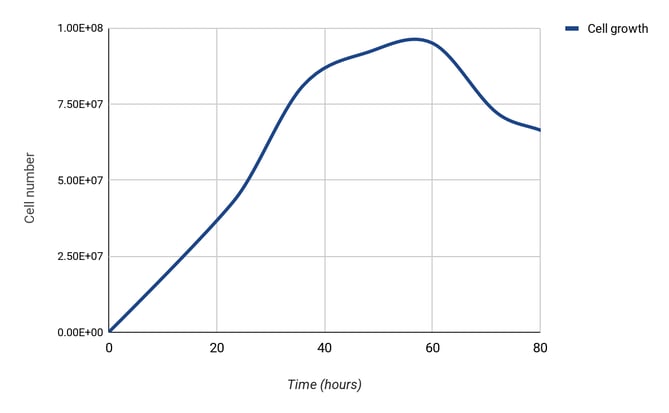

An important aspect to yeast health is ensuring the culture undergoes a healthy growth phase in the initial 4-8 hours of fermentation. This is the time when cells take up oxygen, rebuild sterols and fatty acids for cell membranes, store nutrients, and begin budding and dividing. Yeast health at this stage is directly tied to two key brewer controls; pitch rate and oxygen.

Pitch Rate

Yeast prefer to grow until they reach the population needed for fermentation because yeast are able to produce much more energy per glucose molecule when oxygen is present. The total cell population undergoing fermentation is reach once oxygen is no longer available. This total cell population is what the brewer can control by balancing pitch rate with dissolved oxygen (DO).

For healthy yeast, it is imperative to accurately pitch the correct amount of yeast for a given batch.

Underpitching may result in failure to reach the necessary total cell population which can lead to slow or stalled fermentations, off-flavors, or poor biomass for harvest.

Overpitching can lead to reduced cellular division, resulting in a population with fewer young, healthy yeast cells. These cultures with older cells remaining in each subsequent fermentation will show less vitality and ultimately limit the number of harvestable generations.

White Labs recommends the following pitching rate ranges depending on the fermentation parameters of batch volume, pitching temperature, and original gravity.

Standard Pitching Rates: 0.45 - 1 million cells/mL/P (5 - 10 million cells/mL)

- Low to moderate gravity (Below 18P or 1.072)

- Ale fermentation temperatures (Above 61℉ or 16℃)

- Lower range for yeast-forward styles

High Pitching Rates: 1 - 1.5 million cells/mL/P (12+ million cells/mL)

- Moderate to high gravity (Above 18P or 1.072)

- Cool fermentation temperatures (Below 61℉/16℃)

For a more precise recommending, check out our pitch rate calculator on yeastman.com! Simply enter your batch volume, pitching temperature, and starting gravity.

Dissolved Oxygen

Dissolved oxygen (DO) is essential for yeast growth because oxygen determines how much sterol synthesis can happen. If sterol synthesis is limited or insufficient, this will directly limit growth. Additionally, it allows yeast to build healthy cell membranes to withstand the environmental stresses like sugar density, low pH, temperature fluctuations, and ethanol concentration. An inability to properly handle stressors will directly affect yeast vitality.

The target range for optimal DO in wort prior to fermentation is 8-12 ppm, or 1ppm per degree plato for higher gravity beers. It is recommended to use a DO Meter to confirm target ppm is satisfied, otherwise this measurement is determined simply by estimation.

Proper Oxygen supports yeast health by:

-

- Improving cell growth

- Improving fermentation rate

- Improving attenuation

- Minimizing cell stress

- Control of flavor compounds

- Improving shelf life/storage of yeast slurry

- Improper Oxygen can lead to:

- Incomplete fermentations

- Flavor issues

- Low viability

Health in Active Fermentation

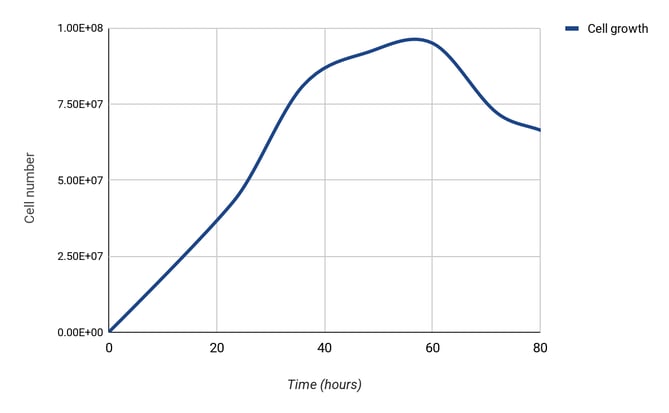

Yeast health can additionally be monitored and tracked after yeast growth in the early lag phase. During active fermentation, simple measurements can provide the brewer insight into the quality of the fermentation.

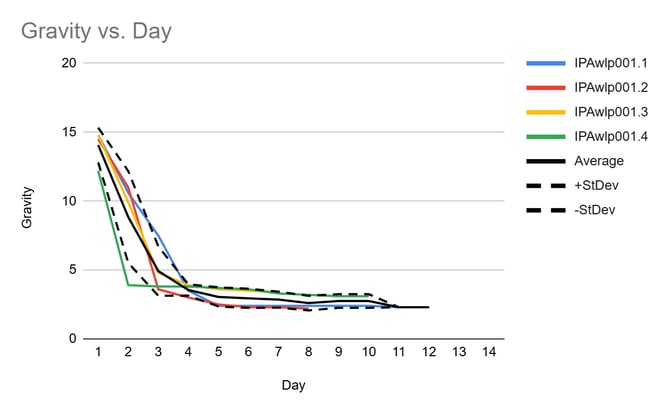

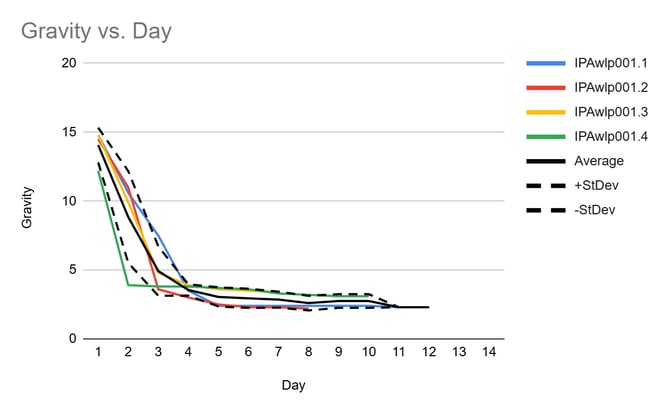

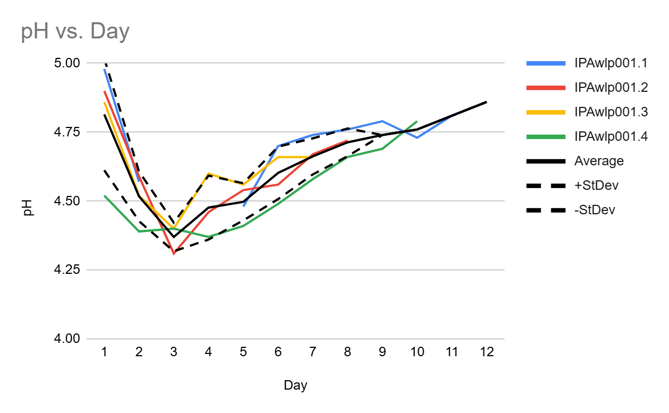

Daily gravity and pH readings will provide clarity on the health of a yeast culture. Both measurements should display large drops in the first 48-72 hours of fermentation signaling an active culture undergoing a vigorous fermentation. If these are not observed, it may indicate the culture's lacking viability or vitality. In this case, we would recommend to avoid re-pitching this culture in subsequent batches.

Top tip: Many breweries routinely brew core brands and can benefit from the graphs below. To track yeast health and quickly notice any fluctuations in performance, plot the gravity and pH means and standard deviations from multiple batches to establish an "on-target" fermentation profile. Quality fermentations with healthy yeast should display consistency and trend within the dotted lines of the standard deviation.

Maintaining Health During Harvest & Storage

After dialing in all previous steps; confirmed a culture is healthy, provided the proper nutrients, and observed a quality fermentation, the last step is to properly harvest and store the culture to preserve its viability and vitality.

Harvest

It's important to collect yeast in a healthy state, meaning don't wait to harvest until the health could be adversely affected:

- Limit time yeast is in the cone of a conical fermenter

- Yeast slurry can be 10F+ warmer in center due to insulation and "hot spots"

- Biomass at harvest is strain dependent

- Removing slurry at or near terminal gravity is ideal in most situations

Storage

The goal of storage is to keep metabolic activity to a minimum to preserve viability and vitality:

- Store around 33-36F

- Ideally as short as possible, storage time highly strain dependent

- Avoid oxygen pick-up, causes rapid depletion of glycogen reserves

- Vent pressure as CO2 can build up and quickly drop the viability of stored yeast slurries

Check out the White Labs FlexBrink®, a durable, 3-in-1 vessel for yeast collection, storage, and re-pitching. Pre-sterilized for a contamination-free process, it ensures high visibility and measurability.

Conclusion

Mastering yeast health is the difference between a good beer and a consistent, world-class brand. By controlling critical inputs like pitch rate, oxygen, and nutrition and verifying them with daily data, you ensure your culture remains vital for generations to come. Don't leave your fermentation to chance; collect and analyze your data so you hit your exact targets and keep your yeast thriving.