Tropical flavors. Fruit bomb beers. Unlocking bound thiols. These are buzz phrases often tossed around whenever the topic turns to biotransformation. In reality, the biotransformation of hop compounds by yeast strains in beer is a fascinating and multifaceted process embraced with great excitement and enthusiasm. Brewers are right to be intrigued, given the clear potential to optimize hops and create evermore diverse and desirable beers.

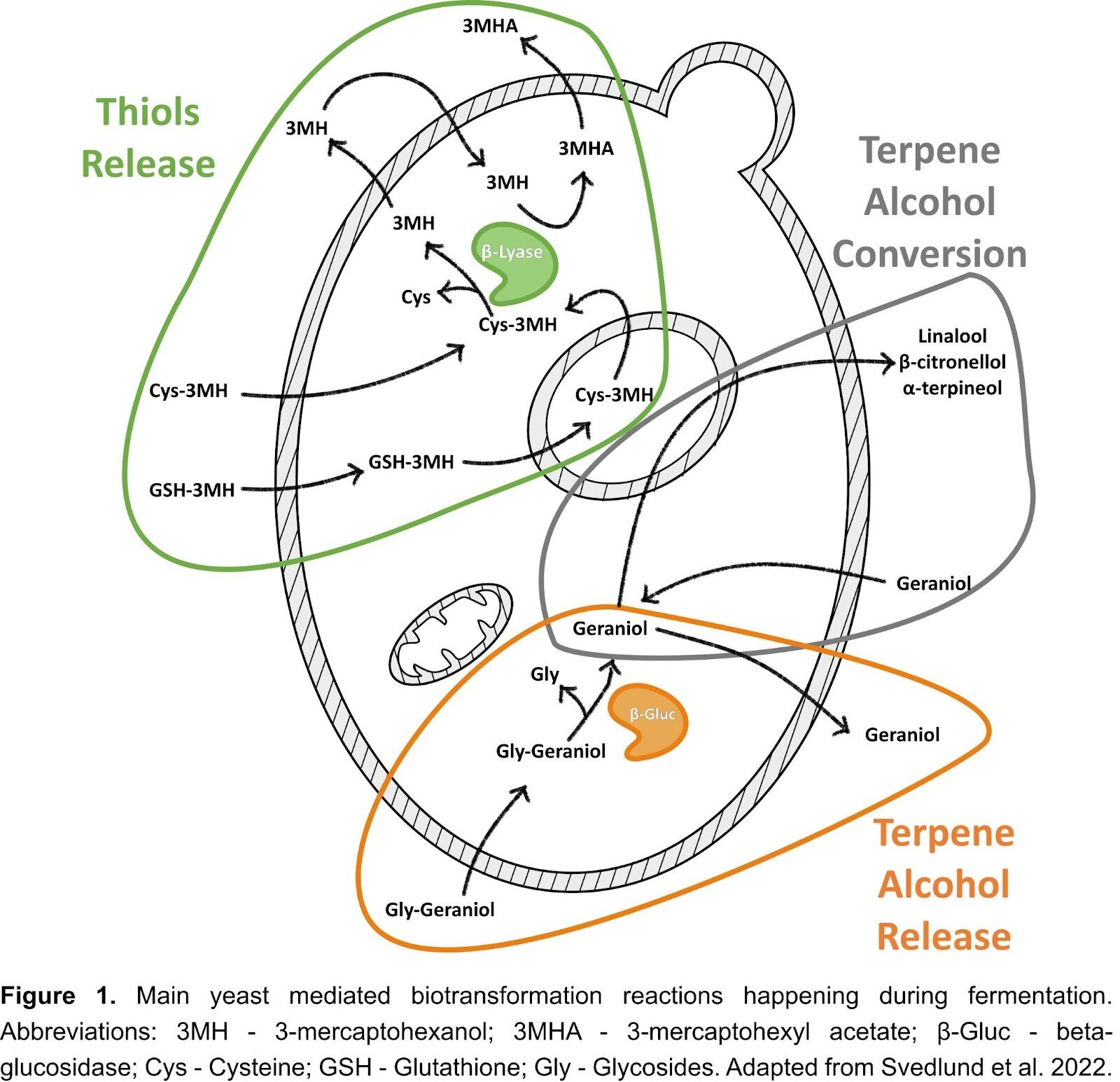

During fermentation, biotransformation occurs when some yeast-derived enzymes convert odorless and flavorless hop precursors into desirable flavors and aromas (Fig.1), making it particularly relevant for popular styles like juicy and fruity IPAs.

Research on this subject is constantly emerging, with much of the knowledge borrowed from the wine industry. This complex process involves three main reactions: i) Terpene alcohol release, ii) Conversion, and iii) Thiol release.

Terpene Release

The main contribution of biotransformation to the final beer is the release of flavor active molecules, like monoterpene alcohols and thiols, from their non-aromatic precursors performed by two yeast-encoded enzymes, β-glucosidase and β-lyase. The conversion between different hop-derived terpene alcohols, like geraniol and linalool, can also moderately contribute to the final product flavor profile. Though not fully understood, this process is also thought to be enzyme-mediated.

The enzyme β-glucosidase releases the aromatic terpene alcohols from a non-aromatic glycoside precursor, such as geraniol from geranyl glycoside. This enzyme is not produced by most brewing strains, being more commonly present in yeast of the Brettanomyces and Pichia genus; thus, the impact of this enzyme is reduced in most beers. Furthermore, the terpene alcohol flavor threshold is reasonably high (ppm to ppb), so a considerable amount of molecules must be released into the beer before its impact is perceived. These molecules can range from aromas of citrus, fruity, or floral notes.

Thiol Release

For that reason, the main focus of brewers and winemakers worldwide is on the reaction performed by the enzyme β-lyase, also known as cysteine S-conjugate beta-lyase. During fermentation, this enzyme releases volatile thiols that contribute notes of passion fruit and grapefruit from precursors in malt and certain hop varieties.

Unlike terpene alcohols, these volatile free-thiols can be detected at extremely low levels, in the parts per trillion range(ppt). Hence, any small increase is likely to be detected by the consumer. Some of these compounds, namely 3-mercaptohexan-1-ol (3MH), 3-mercaptohexyl acetate (3MHA), and 4-methyl-4-mercaptopentan-2-one (4MMP), are known to contribute tropical qualities to the beer aroma.

Not all yeasts are created alike, and only yeast strains that present a functional version of the IRC7 gene can perform this reaction. At White Labs, we screened our entire yeast collection for the presence of this enzyme activity. We developed a blended culture of several high-activity strains, WLP077 Tropicale Yeast Blend, to create the perfect balance of tropical aroma for a juicy, hazy IPA!

Choosing the Right Hops

Hops, as the main source of bound-thiol precursors, also need some consideration as each hop variety contains different types and amounts of compounds that will impact the final flavor profile of the beer.

Some of the most popular hop varieties, like Citra, contribute high amounts of volatile thiols to the beer and do not benefit significantly from biotransformation. On the other hand, more traditional varieties like Cascade, Saaz, or Simcoe contain higher amounts of bound thiols and non-aromatic form. Such hop varieties particularly benefit from interaction with high β-lyase activity yeast strains to achieve tropical aroma profiles.

The challenge for the brewers is to provide the selected yeast strain with plenty of precursors so that the final product presents an improved aroma and flavor. Some of the most popular approaches are introducing hops during the mash and focusing on whirlpool and fermentation hop additions.

Some recent research indicates that whirlpool additions significantly contribute to increased precursor concentration in the wort. Thiol precursors can also be introduced in the brewing process from other sources, namely grape derivative products like Phantasm or even malt, increasing the overall impact in flavor and aroma.

The impact of all these new ingredients and research into dry hopping techniques and hops and yeast interactions are still being assessed, with new information becoming available all the time. Ideas of using traditional hop varieties and yeast with certain enzymatic activity opens the opportunity for new cost-saving methods and even newer beer styles. Stay tuned!