Non-Alcoholic and Low Alcohol Beer

Non-alcoholic beer has been popular internationally for quite some time. More recently, the popularity of these beverages in the US has increased. This category spans beers ranging from <0.5% to about 2.5% ABV. Several methods are used to produce these methods. Not all of them are applicable to the craft beer market but it’s important to understand the different processes used.

Vacuum Distillation

Larger breweries more commonly make these beers with some pricey equipment. One of the methods that produces a beer with <0.5% alcohol is vacuum distillation. This is a method in which the beer is heated and the alcohol is removed via the distillation process. This is a great way to reduce a beer with <0.5% alcohol but can produce a beer that has some undesirable off flavors. The heating process can produce off-flavors typical of beer that has been oxidized or with autolysis. Additionally, this equipment can be quite expensive for a craft brewer.

Membrane Filtration

A second common method is a membrane filtration of a beer, very similar to the process of making RO water. This membrane specific for this process only allows alcohol, color, and some flavor and aroma compounds through the membrane. What results is alcohol and water is removed from the beer. Water is then returned to the concentrated beer. This methodology could be more approachable for smaller craft breweries as there are more accessible equipment coming to the market. One of the main cons with membrane filtration is that much of the flavor can be stripped along with the alcohol, but ultimately this can result with some of the best tasting results.

Brewing non-alcoholic and low-alcohol beers (NAB/LAB) combines traditional techniques with innovative methods to create flavorful beers. As demand rises, new approaches and optimized recipes are delivering better-tasting NAB/LAB options than ever before.

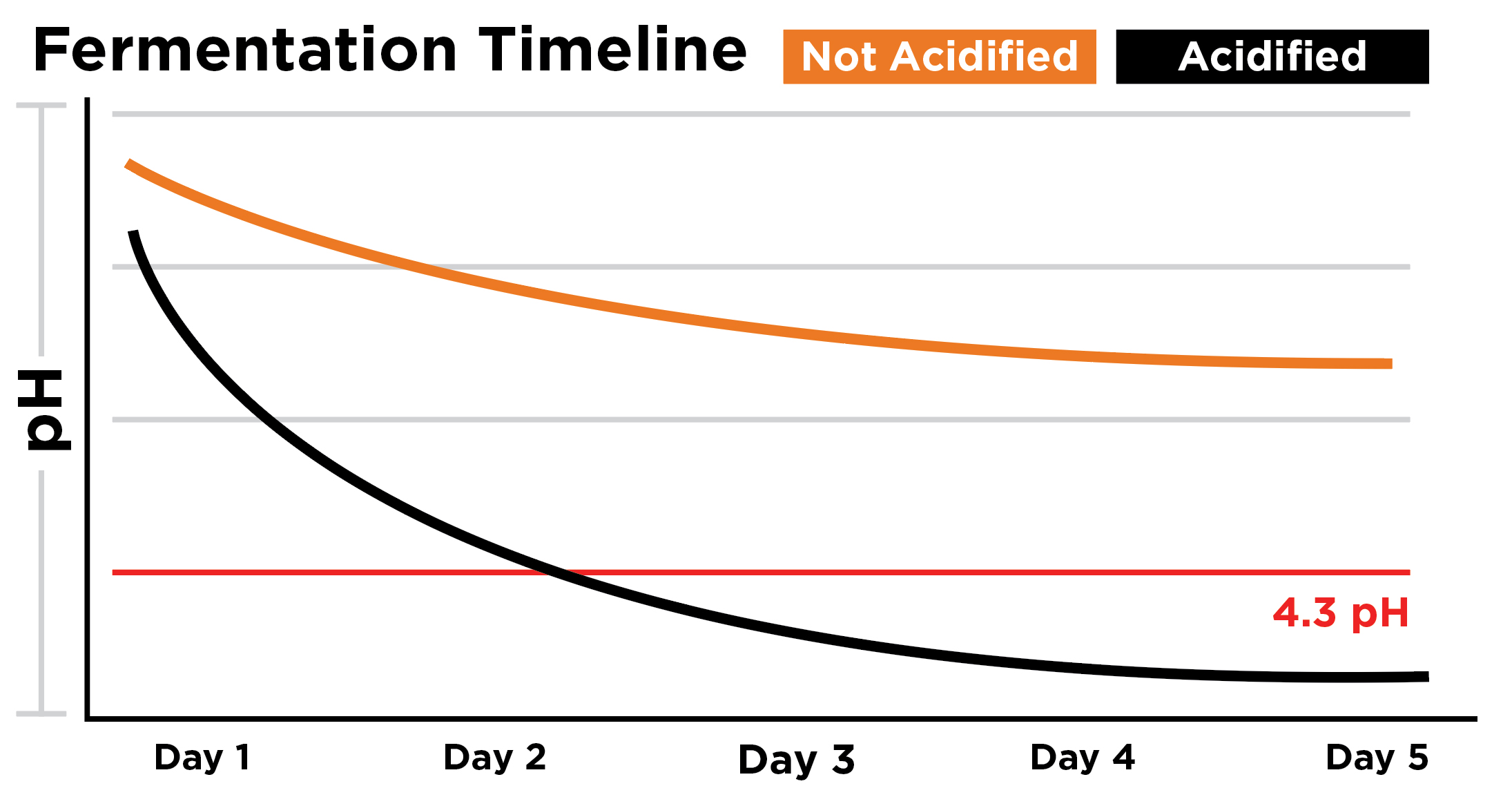

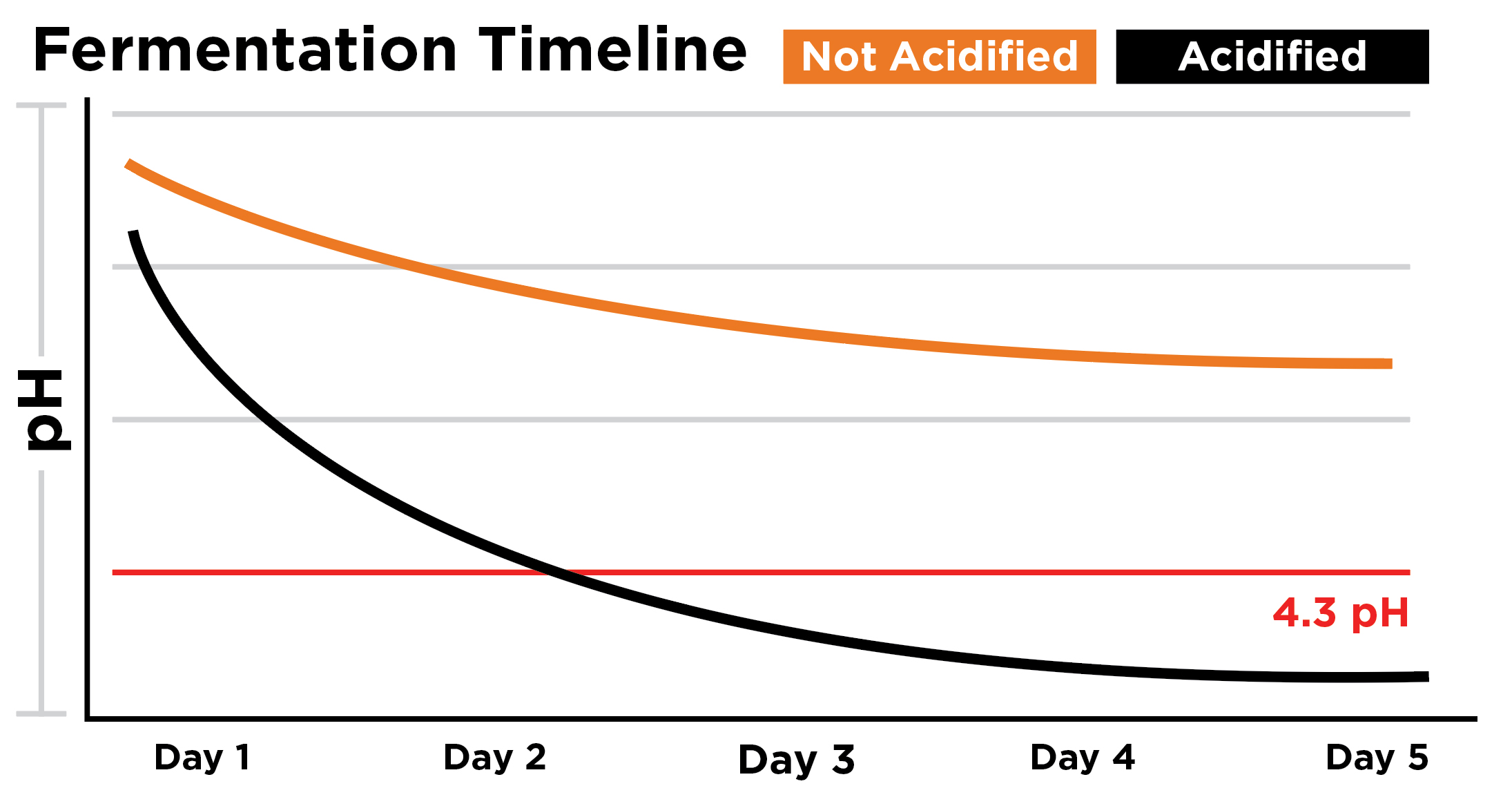

Monitor Your pH

Non-alcoholic and low-alcohol beers lack the typical microbial deterrents found in regular beer due to their lower alcohol content, lower IBU, and higher pH. As a result, greater quality assurance and control are required during their production.

- NOT SAFE FOR CONSUMPTION: Keep pH below <4.3 to prevent the growth of spoilage

microorganisms.

- Adjust your starting pH using phosphoric acid or lactic acid to mimic more of a usual

beer pH drop.

Fermentation

Choose Strains that are Maltose-Negative to Limit Fermentation.

*Professional brewers are able to order the Vault specialty strains at any time, with a 30 day lead time if not in stock

**Glucose and fructose can ferment and produce alcohol with maltose-negative strains.

To limit maltose production:

- Mash at high temperatures (>72°C/162°F) to reduce beta-amylase activity.

- Consider shorter mashes (over 30 minutes).

Pasteurize

- Ensures microbiological stability and extends shelf life.

- NA beer lacks the preservative effect of alcohol, making it more susceptible to spoilage.

- Pasteurization kills remaining microorganisms, preventing spoilage, off-flavors, and health risks.

- Helps maintain the beer’s taste and quality over time.