Every company talks about quality and why it’s important to them, including us. We think what we do to ensure quality, including purity, viability, and performance, really sets us apart from the rest. Here’s why:

21 Long Days of Propagation: Why We Do It

Instead of going 0 to 100, we focus on making yeast that will be best for fermentation, which means taking our time. We have the highest viability because of our 21-day process, resulting in big, plump cells full of nutrients and healthy cell membranes great for sustained viability and reuse.

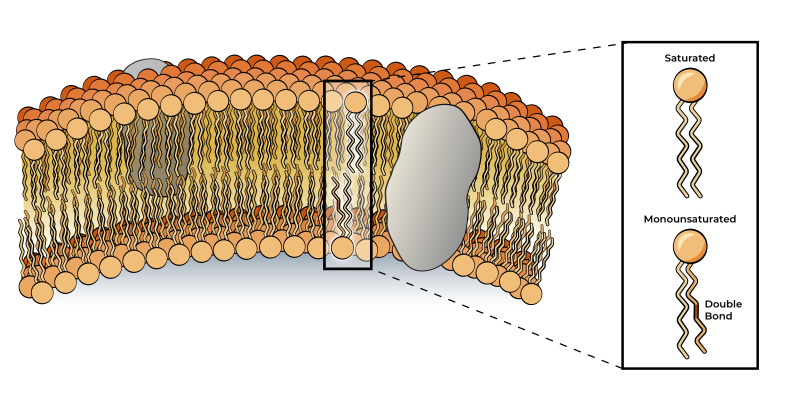

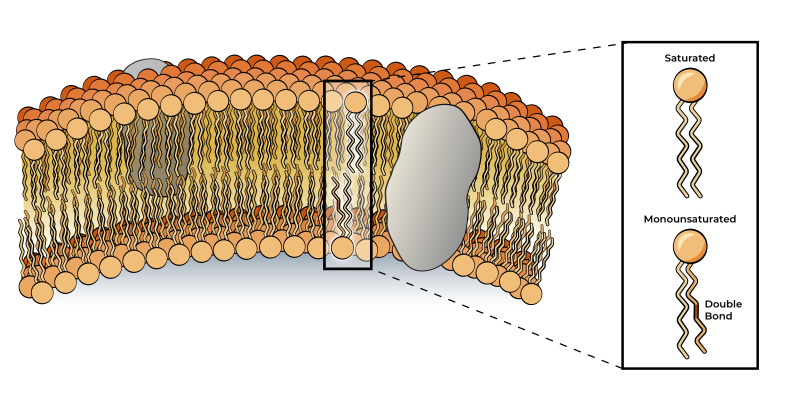

This process ensures that at each step, yeast is effectively intaking the necessary nutrients and vitamins to build robust cell membranes, which are needed to thrive in the harsh environment of fermentation. Sturdy cell membranes are critical to yeast and successful fermentation. Transportation of compounds such as fermentable sugars and nutrients, as well as control of “off-flavor” metabolites, is more effective and efficient, leading to better attenuation and quicker beer maturation.

Yeast with membranes that are deficient in lipids and other cell membrane components will have harder time-consuming nutrients, making them far less healthy and capable of completing fermentation.

Figure 1. Illustration of Cell Membrane of Saturated and Monosaturated phospholipids. Monounsaturated lipids help ease the transportation of compounds.

Small but Mighty

All of our cultures are grown in controlled small batches, from 1 Liter to 400 Liter. Although the bigger scale seems significant to us, these would be considered lab scale to any commercial manufacturing companies!

Figure 2. Illustration of Yeast Cell

We propagate these small batches because they provide benefits in ways you may not think of:

- Optimized propagation recipes for different strains utilizing our own brewhouse, so each strain can be provided with their ideal carbohydrate profile for growth, making the yeast much more efficient fermenters.

- Quality checks on each individual batch mean real-time, verified QC clears on every lot that you can see on our Certificate of Quality.

- 80+ different strains that clear the quality control process every day and week, resulting in the freshest cultures and biggest strain variety.

We worry about the yeast, so you don’t have to, and we don’t do it because it's easy or inexpensive. All of this takes time, and we’re lucky to have a team of awesome science folks who make this their passion every day.

We also rely on our Analytical Lab and Brewing Co for research & development through real-world brewing applications for our yeast and utilizing our lab to learn parameters such as attenuation, nitrogen requirements, different flavor profiles, and timelines. We can help learn and educate on how our strains can be utilized and optimized for the best performance.

The people behind the yeast

To us, quality isn’t just about the purity of our cultures, it extends throughout all our departments.

- Our planning team keeps inventory of what’s in stock and ensures the variety of yeast you want is there for you.

- Our friendly Sales and Customer Service Team helps answer and troubleshoot any question.

- Our production and packaging team are meticulous in their processes to help produce the best yeast possible.

- Our Yeast and Analytical Lab teams test for 38 quality checkpoints on the yeast and also help analyze finished products.

- Our Brewing Team helps provide R&D about our yeast strains and brews various propagation recipes to help maximize our yeast production.

- Our Education department accommodates tours when you’re at one of our tasting rooms, or hosting our Yeast Essentials, giving hands-on yeast handling best practices.

- Our Fulfillment and Shipping teams ensure cold packaging and accurate delivery, having your yeast arrives in pristine condition.

We take the utmost pride in delivering the best quality and experience when you work with us, and we live to help you make the best beverage possible. Cheers!