Oxygen is something brewers inevitably want to minimize in their process, with one exception: wort oxygenation. In other aspects of beer production, oxygen causes detrimental effects on flavor and stability, but the opposite is true in the early phases of fermentation. Yeast depends on oxygen to provide them with the building blocks needed to synthesize fatty acids and sterols, essential components in the yeast cell membrane. Oxygen also contributes to the formation of hemoproteins, which help the cells protect themselves from oxidative stress, critical in a fermentation environment.

This concept is not particularly new to brewers. The main challenge over the years has not been the “what” of oxygenation but the “how.” As crucial a piece as this is, it is a much more difficult task to oxygenate wort properly and adequately.

Need a better way to oxygenate on a Homebrew System? Check out the Spike Oxygenation Kit and our AMA with them!

How much oxygen do you need?

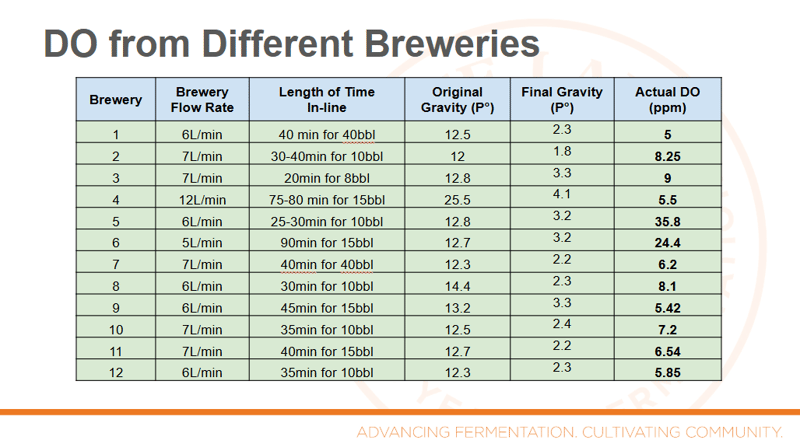

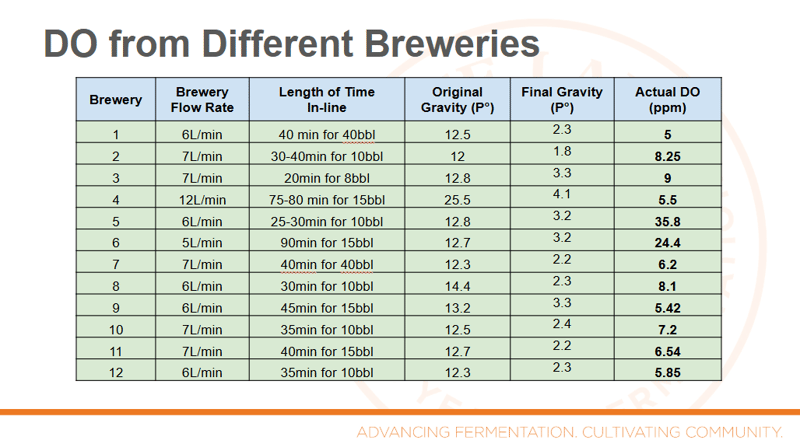

Most texts will recommend a standard dissolved oxygen rate of 8-10ppm (mg/L) in a moderate gravity wort (up to 12° Plato). Another rule of thumb, is 1ppm per Degree of Plato. The key here is understanding that we’re talking about dissolved oxygen and the oxygen dissolution rate in wort can be dependent on a number of factors including temperature of the wort, gravity of the wort, and size of the bubbles.

What happens when you don’t oxygenate enough?

Technical data found in many brewing journals, and in our studies, it is clear that an increase in available oxygen in the wort results in a higher budding percentage and therefore, higher cell growth and more effective fermentation capability.

Are Craft Brewers Underaerating Their Wort?

In fermentations where no additional oxygen is added, yeast never reach the cell mass obtained in oxygen-enhanced fermentations, resulting in long lag times and sometimes, not reaching the expected terminal gravity. Fermentation with a dissolved oxygen process in place, reach terminal gravity faster than the controls (with no oxygen added).

If you repitch yeast, the long-term effects of reduced oxygen levels on multiple yeast generations is also significant. When the yeast is deprived of adequate oxygen levels early on, it causes weaker cells in later generations. This is most significant after the third generation. These yeast cells do have not had ample resources to build up solid cell walls, resulting in fewer cells with glycogen reserves and membranes that can withstand the stress of fermentation and the alcoholic, low pH environment of beer.

Air vs. Oxygen

While it’s fine to use air (or shaking, splashing, or other manner of physical air delivery), from an efficiency standpoint, it is not an ideal method. When you consider that air is 21% oxygen, you have lost a bit of your dissolution rate. In this case, the maximum solubility is only around 9.5ppm, and backpressure is usually needed to keep oxygen in the solution.

When working with pure oxygen, your maximum potential dissolved oxygen (DO) jumps to 40ppm (saturation). Other factors keep DO levels from landing at saturation, such as the temperature and gravity as mentioned before, as well as the flow rate and time of oxygenation.

Figure 1. Dissolved Oxygen Levels from Different Breweries. The proper way to check is with a DO meter in a fermentor.

It is important in this regard to find an efficient method for wort oxygenation, whether through a small tank and carbonation stone on a small scale, or inline oxygenation with a larger brewing facility. While there is not necessarily a “standard” process, there are a few primary factors that will affect the efficiency of oxygen dissolving in wort:

1. The cooler the wort, the better the dissolution of oxygen.

2. The higher the gravity, the less efficiency of the dissolution of oxygen.

3. The smaller the bubble, the more efficient the dissolution of oxygen.

Keep these factors in mind in relation to your own process, and make adjustments in your aeration process as needed.

The bottom line? Yeast loves oxygen and yeast makes beer. So oxygenate your wort!