Enzymes are a fundamental part of the brewing process, mediating steps as vital as sugar and flavor extraction from raw materials or off-flavors removal in the final product. Different enzyme families are responsible for different tasks in the brewing process, and the careful manipulation of temperature and pH allows the brewer to choose which enzymes are active and what functions are performed.

These commercially available enzyme products contribute to significant economic savings, allowing the utilization of alternative raw materials, improving water and energy usage, or decreasing tank time.

White Labs Copenhagen is proud to announce 3 new enzymes to make the brewing process easier than ever before!

*Only Available to White Lab Copenhagen Customers

For producing highly fermentable wort or compensating for the utilization of raw materials with lower or no enzyme activity. Candy is a blend of 2 different enzymes of glucoamylase and pullulanase. Perfect for producing highly fermentable wort or compensating for using raw materials with lower or no enzyme activity.

As agricultural products, the main raw materials in beer present regional and seasonal variability that, coupled with supply chain disruptions, challenges the brewer's capacity to achieve predictable flavor and sugar extractions and, consequently, a consistent final product. Furthermore, the industry is increasingly focusing on cost-effective and sustainable alternative raw materials due to rising cost pressures.

As agricultural products, the main raw materials in beer present regional and seasonal variability that, coupled with supply chain disruptions, challenges the brewer's capacity to achieve predictable flavor and sugar extractions and, consequently, a consistent final product. Furthermore, the industry is increasingly focusing on cost-effective and sustainable alternative raw materials due to rising cost pressures.

Glucoamylase

These enzymes also act on the α-1,4-glucosidic linkages of starch and dextrins, but specifically on the final glucose unit of the non-reducing end of the molecule.

Pullulanase

Pullulanases act on the α-1,6-glucosidic linkages of the branched part of starch, the amylopectin. This produces linear dextrin molecules that act as substrates for enzymes like glucoamylase and/or α-amylase, significantly increasing the starch breakdown. Commercially available formulations usually contain pullulanase combined with one or more such enzymes.

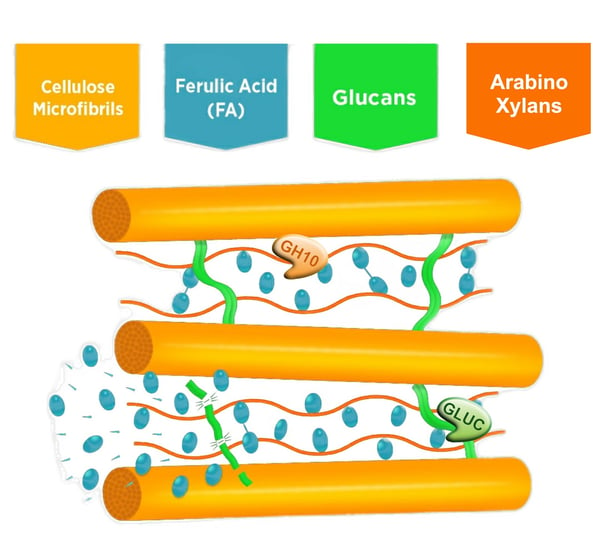

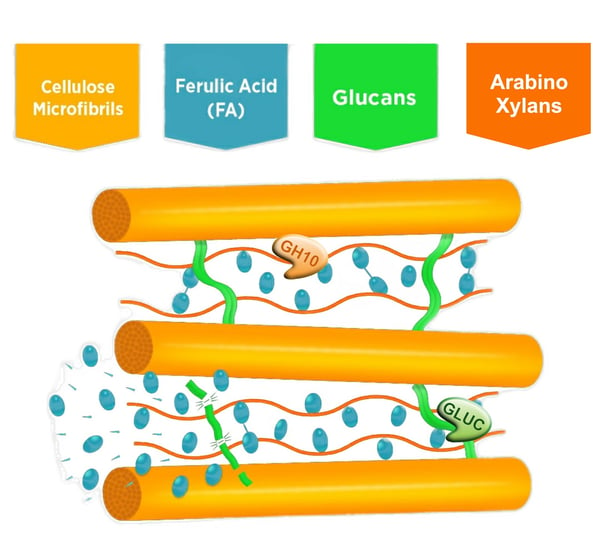

Faster run-off in the lauter tun due to a lower viscosity, better wort separation, and improved yields

The rising energy costs and raw materials press brewers to optimize their brewing process constantly, and the wort and beer filtration steps are obvious choices to save time while increasing output. During mashing, large molecules are extracted from the grain's cell walls, namely beta-glucans, and arabinoxylans, and negatively influence the time and yields of the downstream filtration steps. Breaking these large molecules into smaller polysaccharides will contribute to faster run-off in the lauter tun due to a lower viscosity, better wort separation, and improved yields.

Endo-β-glucanase

The endo-β-glucanase enzymes break the 1,3– or 1,4- bonds in β-glucans. Some are capable of hydrolyzing both bonds, considerably speeding the process.

Commercial formulations include thermostable enzymes that stay active during the entire mashing, up to 70-75°C. The activity of these enzymes also contributes to releasing higher amounts of ferulic acid, the precursor that gets converted to 4-vinylguaiacol by POF+ yeast strains.

Endo-xylanase

Endo-xylanases hydrolyze 1,4-xylosidic bonds in xylans, but different enzyme families can cleave xylans chemically bound to other molecules, namely the GH10 and GH11 families. In brewing, endo-xylanases capable of degrading xylans connected to arabinose residues are of particular interest. Endo-xylanases belonging to the GH10 family are capable of cleaving arabinose-rich xylans into smaller polysaccharides, and contribute to a significant reduction of viscosity in the wort.

Significantly reduce diacetyl formation and the need for extended tank time. Extending tank time is a common strategy to address the presence of unwanted off-flavors in beer. Frequently, the extra time in the presence of yeast will allow the conversion to less offensive compounds and allow the beer to be released for consumption. However, the unplanned extra fermentation time on a particular beer contributes to production plan disruption and added costs. Diacetyl and the diacetyl precursor, α-acetolactate, are formed through amino acid synthesis of Valine. This precursor can present itself through pH change and oxidation, leaving Diacetyl bombs in beer.

Acetolactate decarboxylase

This enzyme acts on the diacetyl precursor, α-acetolactate, and converts it directly into the flavorless compound acetoin in the beer. This fast enzymatic reaction competes with the slow spontaneous formation of diacetyl, and can prevent the formation of diacetyl (Fig. 3). This enzyme also prevents the slow formation of diacetyl after the yeast was removed from the beer in packaging. Nevertheless, this enzyme does not act on diacetyl, so when the diacetyl is already present in the beer, the conversion to acetoin depends on the yeast cells and extended warm rest.