Free Amino Nitrogen (FAN) is a critical parameter in beer analysis that leads to healthy fermentation, and, thus better beer quality. It is a measure of the concentration of amino acids and small peptides that are essential for yeast metabolism. In simpler terms, it indicates the amount of food available for yeast, helping them convert sugar into alcohol during the brewing process more effectively.

FAN levels are determined using various analytical techniques such as spectrophotometry, enzymatic assays, and chromatography. These techniques measure different aspects of amino acid levels, and the results are often reported in units such as mg/L (ppm) or g/L. A general rule of thumb is that a level of at least 150 mg/L is ideal for standard beer fermentation.

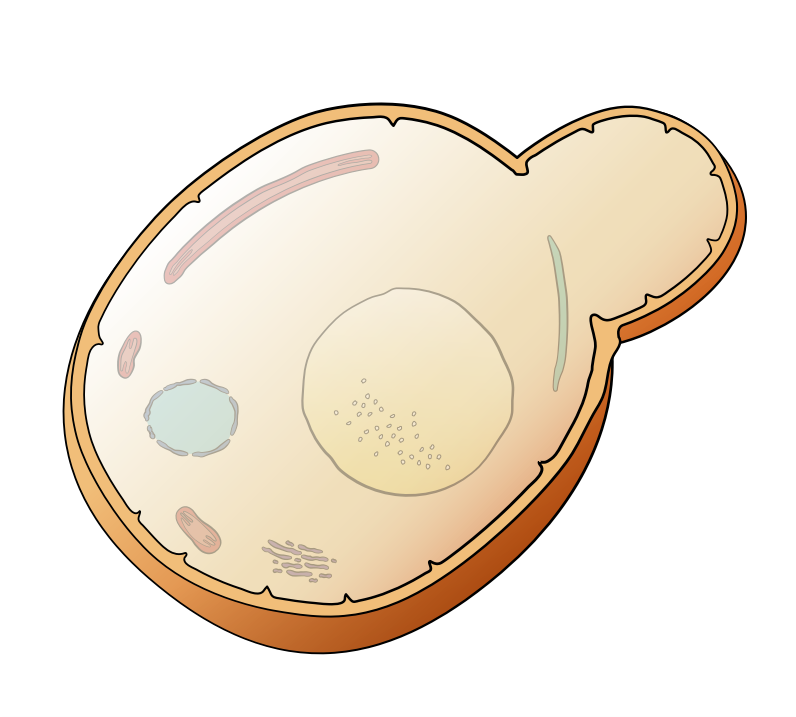

Low levels of FAN can lead to slow or incomplete fermentation. Yeast needs sufficient nitrogen to carry out fermentation efficiently, and anything lower than the optimal level can inhibit this process. The presence of FAN in a beer affects vital aspects such as the fermentation rate, attenuation, aroma, and yeast vitality. Yeast use FAN as a key source of nutrients during fermentation, particularly in the initial stages of fermentation.

As a result, the concentration of FAN in a beer can affect the fermentation rate and, ultimately, the alcohol content and carbonation of the final product. FAN also plays a role in yeast vitality, which ensures the beer is free of off-flavors and aromas. Inadequate FAN levels can lead to stressed yeast, producing undesirable flavors and aromas such as diacetyl, acetaldehyde, and sulfur compounds.

Brewers can influence FAN levels in beer through various techniques, such as selecting brewing grains and adjuncts or adding exogenous nutrients. For example, malted grains such as barley are a rich source of amino acids, and including these in larger amounts in a beer recipe can increase FAN levels. Similarly, adding yeast nutrients before fermentation can help maintain FAN levels in the optimal range.

An all-malt wort is usually sufficient in nitrogen content for a complete fermentation. Brewing High Gravity Beers or adding large amounts of adjuncts such as rice, sugar, juice, or honey would require an extra nutrient addition.

Adding large amounts of adjuncts such as rice, sugar, juice, or honey would require an extra nutrient addition. Two great products to add additional amino acids to your wort are FANMax Bio™ or SeltzerMax™. If you’re producing products such as mead, seltzer, or wine, extra nutrients almost always need to be added for a successful fermentation.

Adding large amounts of adjuncts such as rice, sugar, juice, or honey would require an extra nutrient addition. Two great products to add additional amino acids to your wort are FANMax Bio™ or SeltzerMax™. If you’re producing products such as mead, seltzer, or wine, extra nutrients almost always need to be added for a successful fermentation.

These types of fermentations require Yeast Assimilable Nitrogen (YAN) analysis that includes FAN in addition to ammonium ions and urea (Inorganic Nitrogen).

In summary, Free Amino Nitrogen is a crucial parameter in beer analysis that impacts the quality and taste of beer. Brewers must pay close attention to FAN levels and take appropriate measures to ensure these remain within the optimal range for efficient fermentation and producing high-quality beer.

An all-organic version of nutrients, FANMax Bio™, is excellent for providing the necessary nutrients and nitrogen needed for healthy fermentations.

This product contains peptone and yeast extract that provides essential fatty acids, free amino nitrogen, nucleic acids, vitamins, and minerals for your yeast.

An excellent product for deficient nitrogen fermentations such as kombucha, wine, or cider.

FANMax Bio contributes around 30ppm of FAN for a dosage of 100g/bbL. We recommend using traditional finings agents for most fermentations. If you are still struggling with unwanted haze, filtration may be necessary.

Why Organic?

Organic nitrogen versus inorganic nitrogen is like comparing maltose to simple sugars. Yeast will metabolize the simple sugars or inorganic nitrogen much quicker but can make them lazy and inefficient later on. Too much inorganic nitrogen can also lead to fusel alcohol off flavors and urea.

SeltzerMax™ is our blend of nutrients that have been specifically designed to create a clean and dry hard seltzer. SeltzerMax™ has been optimized to provide essential nitrogen, vitamins, and minerals for yeast health, resulting in a fast and complete hard seltzer fermentation. SeltzerMax™ can also be used for mead, cider, and kombucha fermentation.

SeltzerMax™ contributes around 95ppm of YAN for a dosage of 100g/bbL. We recommend using traditional finings agents for most fermentations. If you are still struggling with unwanted haze, filtration may be necessary.

Why Inorganic?

By using inorganic nitrogen is it will not have the same yeasty color and taste that is commonly found in organic nitrogen sources such as yeast hulls. Making it optimal for fermentations with minimal flavors that can be overpowered.