The market for gluten-free products is ever increasing. Beer has traditionally not been a product available for the gluten-intolerant crowd. Using a specific enzyme, drinking gluten-reduced beer has now become a reality.

Clarity Ferm® is an enzyme containing proline-specific endo-protease derived from a selected strain of Aspergillus niger.

Clarity Ferm® IS INTENDED FOR TWO BREWING PURPOSES:

- Significantly reduces the gluten in beers brewed with barley and wheat.

- Eliminates the appearance of chill haze.

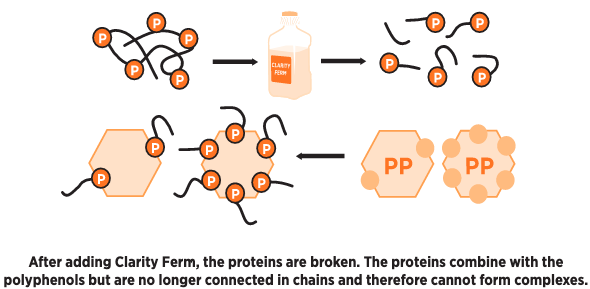

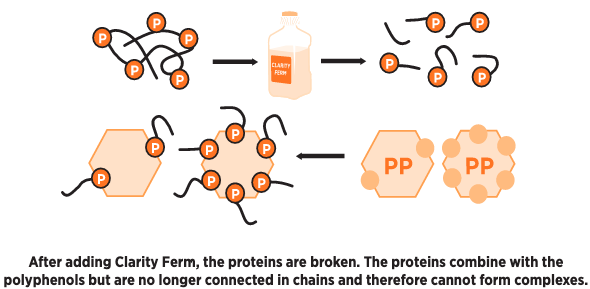

The enzyme cleaves gluten proteins so that people with gluten sensitivities do not react adversely. When used correctly, beers treated with Clarity Ferm® test below 20 ppm of gluten, which is the FDA’s limit for gluten-free products.

Because beer is produced with ingredients that contain gluten, the FDA does not allow beers treated with Clarity Ferm® to be considered gluten-free. Find out more about the FDA ruling on gluten-reduced beers here.

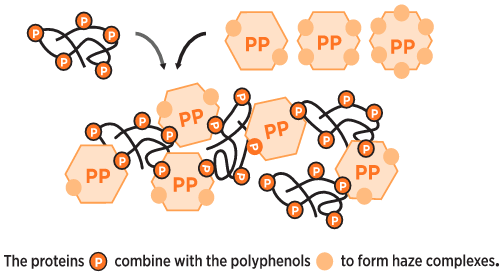

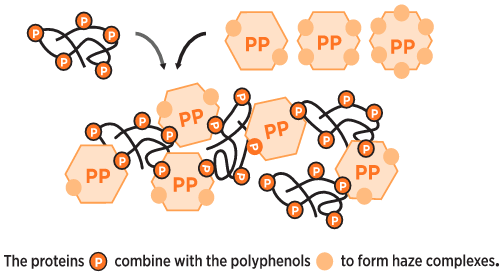

How Does It Work?

Can You Test My Beer For Gluten?

White Labs provides gluten analysis by utilizing the only TTB approved test for gluten, the R-Biopharm RIDASCREEN® Gliadin competitive assay. This is an approved ASBC Method (Beer-49).

When Do You Add It?

It is best to add the enzyme before yeast pitch during knock-out while the wort is being filled. This will ensure proper mixing occurs before fermentation starts. Simply then pitch the yeast after all nutrients & enzymes have been added, while knockout is still occuring.

Once fermentation is complete, the possibility of chill haze will be eliminated, and gluten has been reduced. The beer will be stable, clear, and gluten-reduced.

TIP: For non-vigorous fermentations, it is best to rouse the enzyme back into solution with a CO2 burst

How Much Should You Use?

We’ve done extensive research with this product to understand dosage rates across many style types. For example, wheat contains twice the amount of gluten than barley.

Because each beer is created with different ingredients, we suggest you check out our dosage calculator here for the best results.

How to use the Clarity Ferm® Calculator?

-Pro [1L, 10L] or Homebrew

- For Haze stabilization, select A or B

- For Gluten reduction, select C or D

Enter Gravity (Pro Only) & Batch Size

= Calculated Amount of Clarity Ferm® Needed