Stop Diacetyl in its tracks

Prevent the Formation of Diacetyl during Fermentation.

What is Diacetyl?

What is Diacetyl?

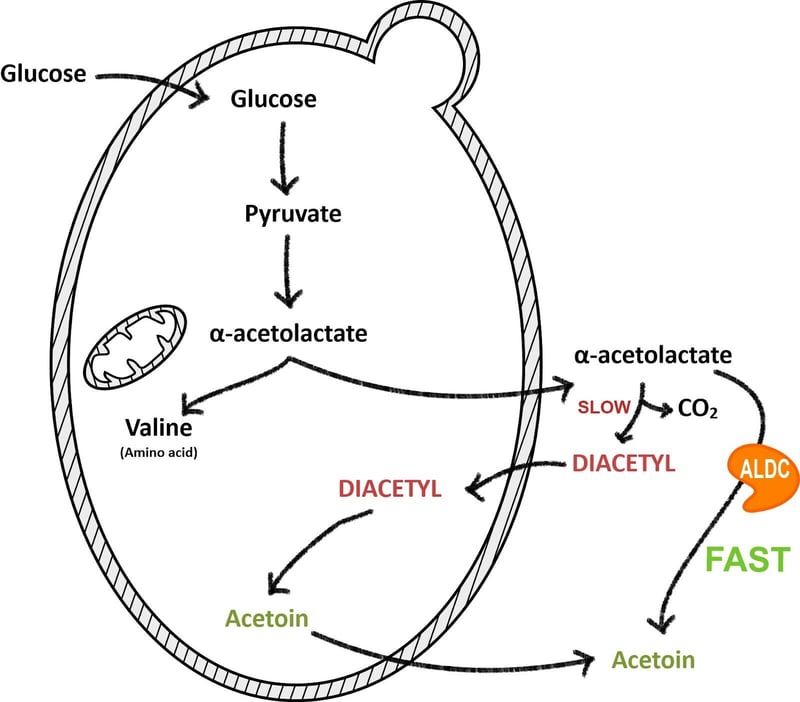

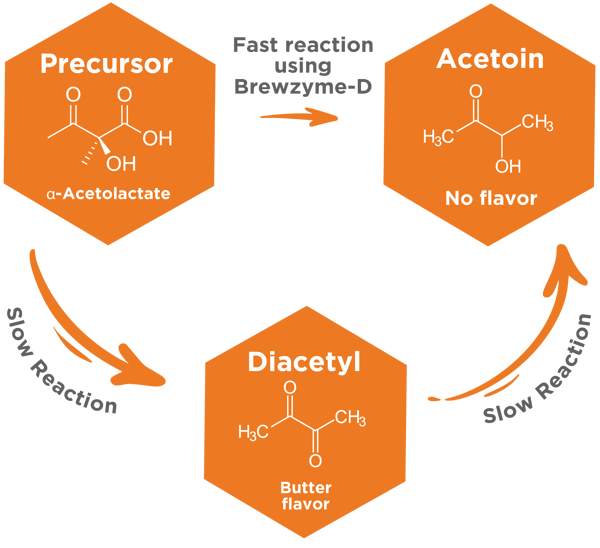

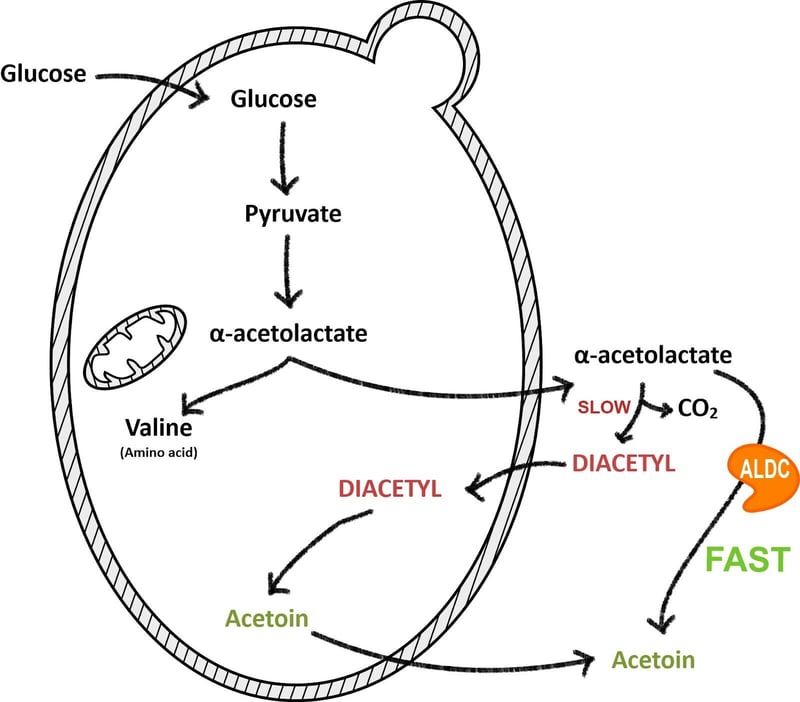

Diacetyl formation is a natural byproduct of yeast fermentation. When yeast consumes sugars, it creates amino acids, mainly valine; meanwhile, α-acetolactate is created as a byproduct of amino acid metabolism.

Excess α-acetolactate leaks out of the yeast cell and is naturally oxidized into diacetyl before being reabsorbed by the yeast cell. At times, this reabsorption can be stalled if fermentation is less active, fermentation temperatures are low, yeast is removed too soon, or other processes are employed, leaving residual diacetyl in the finished beer.

"Off-Flavors" & Longer Tank Times

Diacetyl, a vicinal diketone, is widely regarded as an unpleasant off-flavor in most beer styles. Present at a very low flavor threshold (50-150 ppb), diacetyl contributes a buttery flavor and slick, coating mouthfeel to the beer. After diacetyl is formed, it can only be removed from the beer through reabsorption and conversion by the yeast cells. As fermentation approaches the end, the yeast will uptake the diacetyl and convert it to acetoin, a flavorless compound. Diacetyl is a common reason for extended tank time in beer production due to this slow process.

Unhealthy yeast, highly flocculant strains, and practices such as dry hopping, can all cause problems with diacetyl cleanup. Poor cleanup leaves unwanted diacetyl in the beer. Extending tank residency times and raising the temperature to conduct a diacetyl rest are common strategies used to ensure the reabsorption of diacetyl.

The longer yeast contact time and warmer temperatures aid in the conversion of diacetyl to acetoin, thus reducing the concentration to a level below the flavor threshold. However, the time to perform diacetyl rests, and any unplanned tank residency time can contribute to added costs, production plan disruptions, and less beer produced overall.

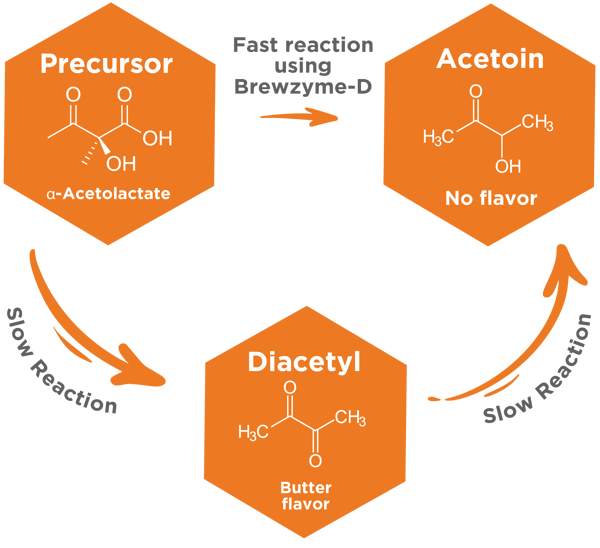

Brewzyme-D is an exogenous enzyme made with α-acetolactate decarboxylase(ALDC). This enzyme breaks down the diacetyl precursor during fermentation thus preventing diacetyl from forming. The use of this enzyme will shorten maturation time and improve overall beer quality. Dose enzyme during yeast pitching and/or at dry hop, as this will cover all types of fermentations. Brewzyme-D will not reduce diacetyl already in the beer as it only affects its precursor.

Dosage:

- Pro (1L, 10L): 15-20mL/hL(0.84 BBL)

- HB (10mL): 10mL/ 20L(5Gal)

Save Time & Money

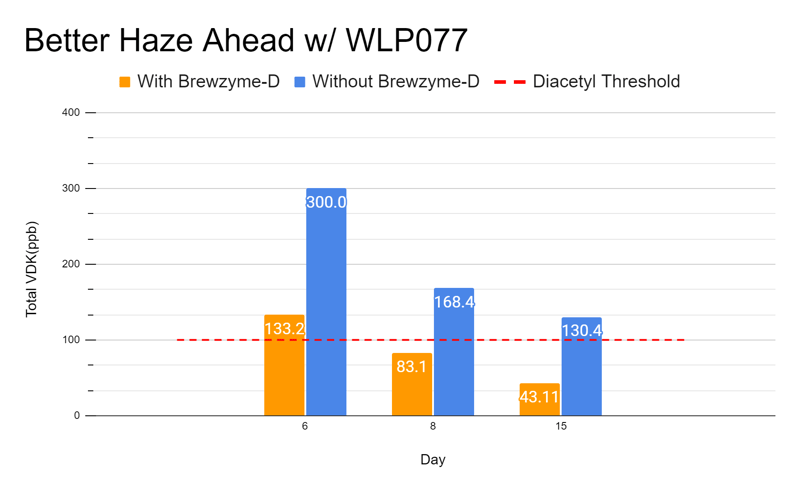

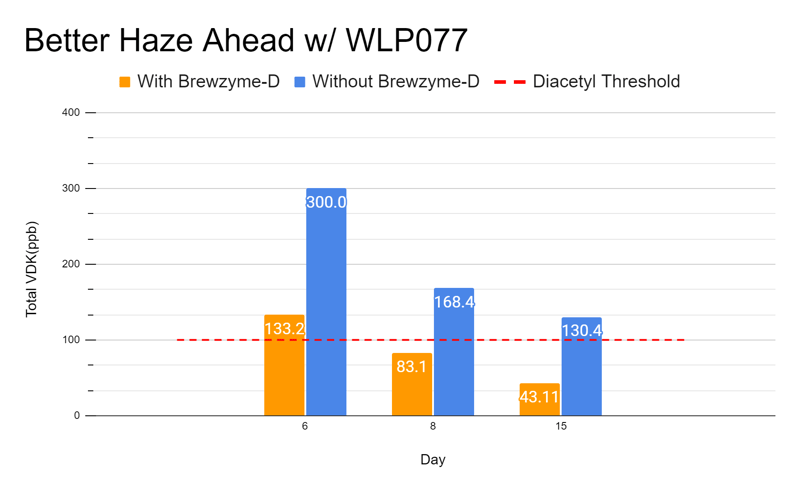

At White Labs Brewing Co, we wanted to analyze tank residency time in our flagship Hazy IPA, Better Haze Ahead. This beer often requires longer diacetyl rests due to its multiple dry-hop additions. We measured the diacetyl potential by quantifying both diacetyl and its precursor, alpha-acetolactate, also known as Total VDK.

In the graph below, the beer using Brewzyme-D helped prevent diacetyl formation. Brewzyme-D was added at the start of fermentation as well another addition was added at the same time as Dry Hopping on Day 3. With the recommended double dosage, the reduction of total diacetyl potential to below the flavor threshold was seen by Day 8. In comparison, the standard fermentation without Brewzyme-D was still above the flavor threshold on Day 15.